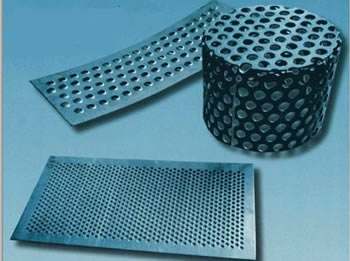

Perforated steel is a steel sheet stamped or punched with a machine to create a pattern of holes. Perforated steel can also be called a perforated plate, perforated sheet, or perforated screen. Perforated steel was developed for the mining industry for use in the filtering of coal. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Our commitment to excellence is reflected in the superior quality of our perforated metal products. We understand the diverse needs of our customers, and our extensive range of perforation patterns and materials ensures that we can meet and exceed expectations across various industries.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Steel Manufacturers

How Perforated Steel is made

The manufacturing process of perforated steel begins with a sheet of steel metal. The most common method of steel perforation uses a rotary pinned perforation roller. A perforation roller is a large cylinder covered in sharp-pointed needles to punch holes into the metal.

The sheet metal is run across the perforation roller. It is rotated continuously while punching holes in the passing sheet. The roller contains needles that are capable of producing different hole sizes. These needles are sometimes heated so the metal can be melted simultaneously, forming a reinforced ring around the perforation.

Another common method of producing perforated steel is called die and punch perforating. A sheet containing needles is repeatedly pressed onto the passing metal during this process. The sheet with needles then punches holes into the sheet. The pieces that remain from the punching will then be sheared off, and the machine will smooth the surface. This method is very efficient and can quickly perforate a sheet with a large surface area.

.Another method that is the most advanced is called laser perforation. This method is precise and sophisticated but also the most expensive. The results of laser perforation are similar to those of rotary pinned perforation with hot needles. The only difference is that laser perforation maintains a higher level of consistency as well as control over the pattern and size of the holes.

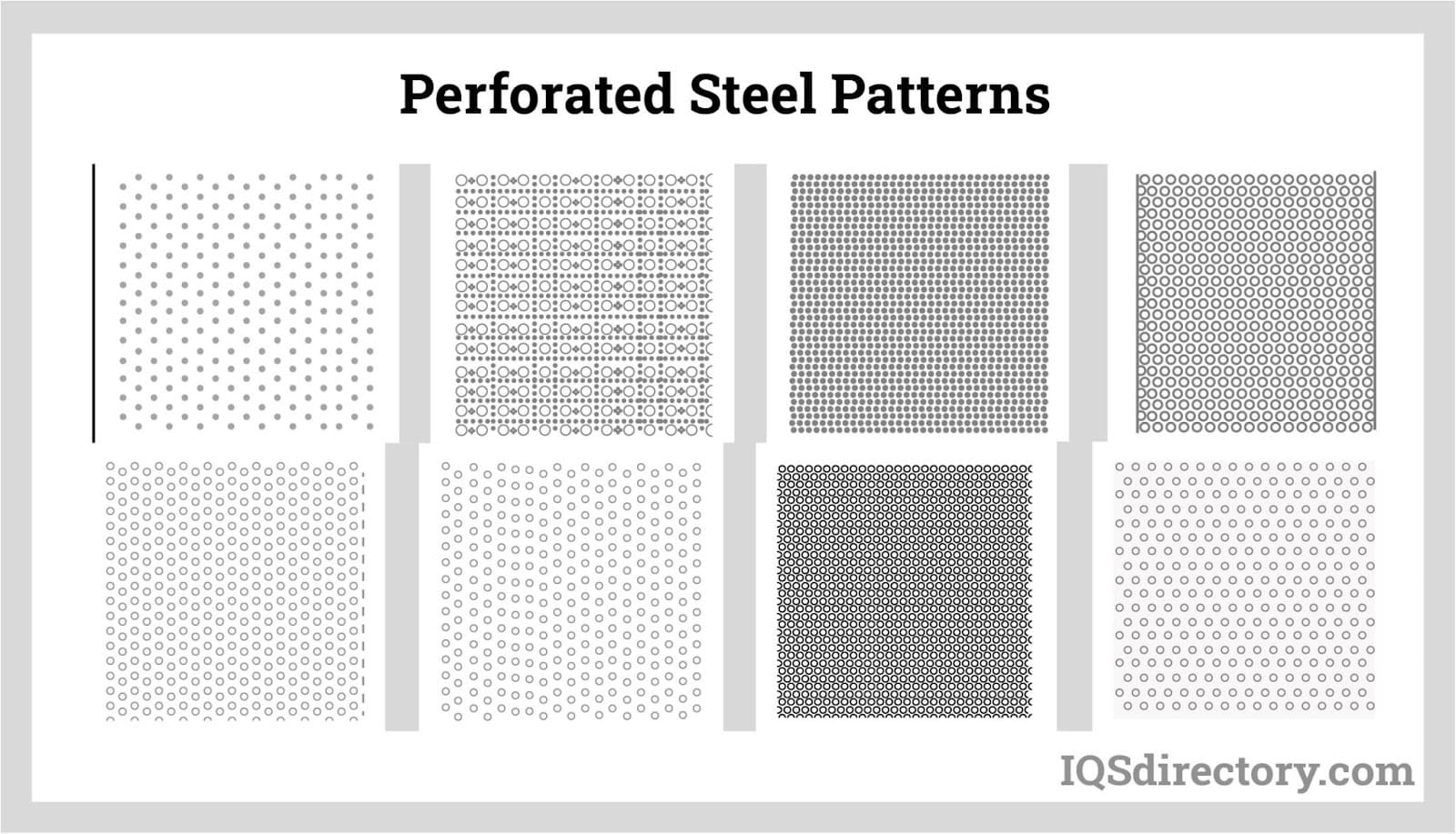

Types of Perforated Steel

The different types of perforated steel include:

Round Hole Perforated Steel

Round perforated steel is cost-effective, requires little maintenance, and is easy to use. Round-hole perforated steel is suited for HVAC system components. It is also ideal for interior design applications.

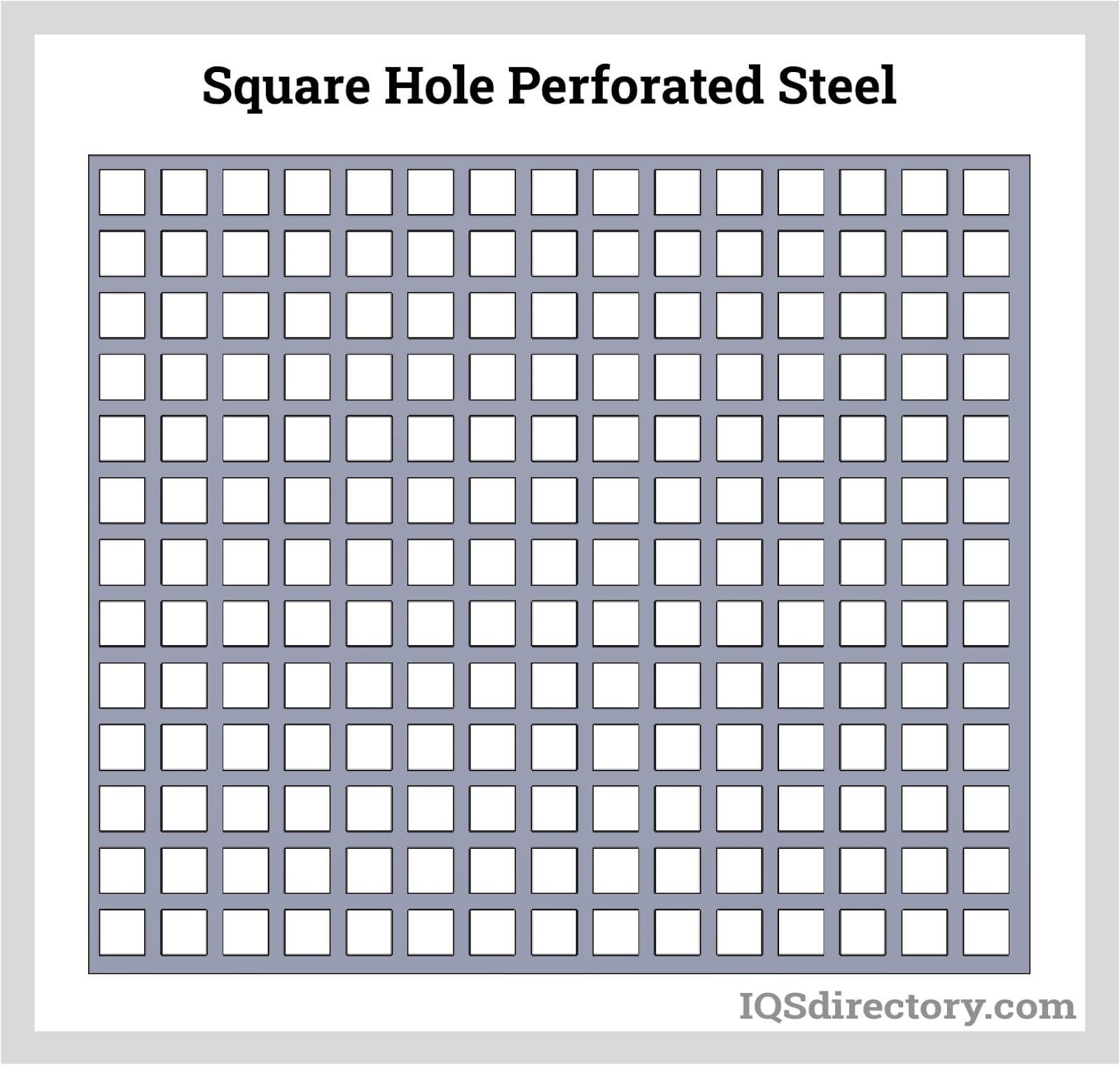

Square Hole Perforated Steel

This type of perforated steel is aesthetically pleasing with a high strength-to-weight ratio. In addition, square-punched holes are larger than other types of holes. As a result, square perforated steel is perfect for a variety of enclosures.

Rectangle Slot Perforated Steel

This perforated steel type is often used in screens and other filtering applications. It also provides strength and is affordable.

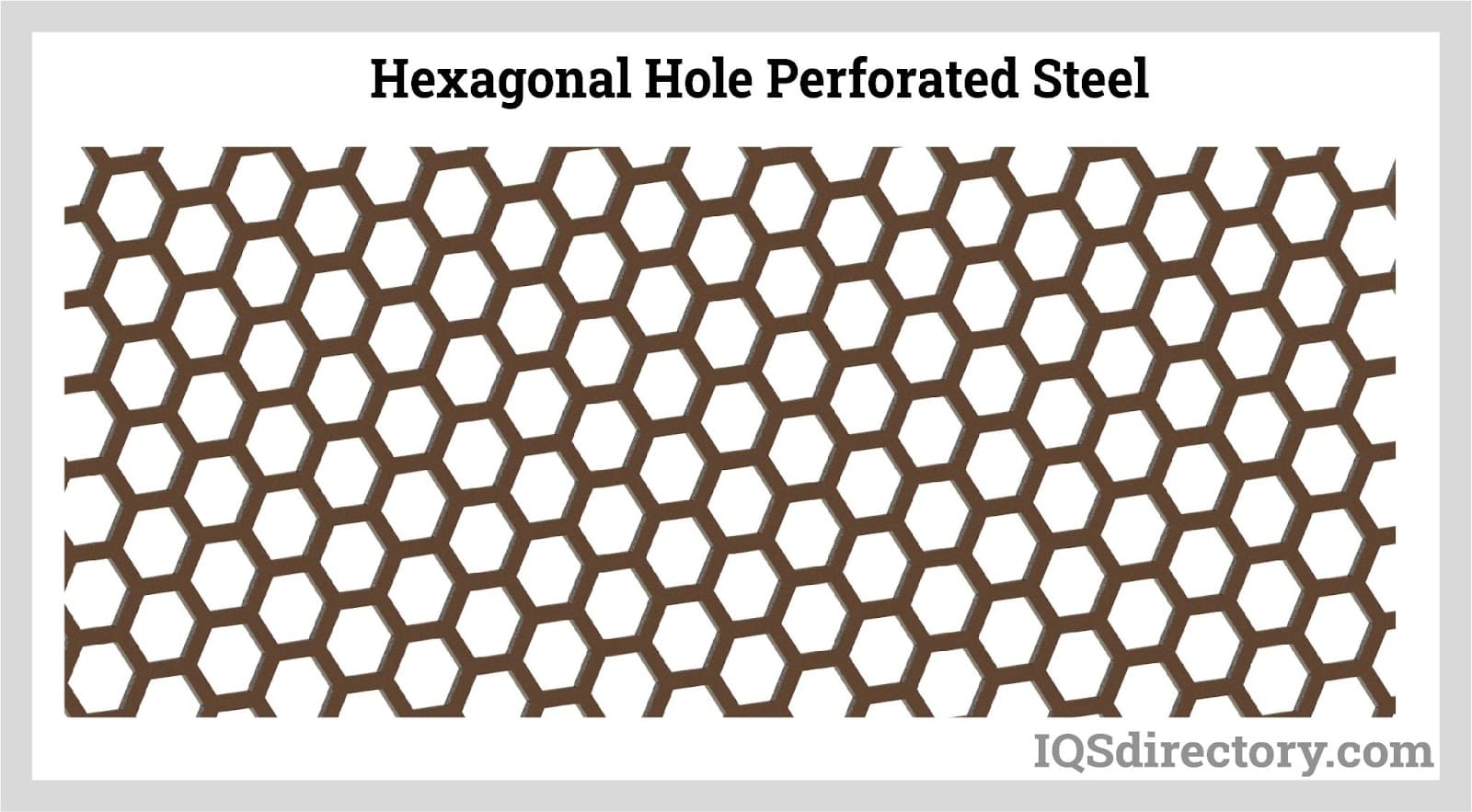

Hexagonal Hole Perforated Steel

This type of perforated steel is popular in industrial and architectural applications. It is a popular option for partitions, interior space dividers, or any other type of unique application.

Applications of Perforated Steel

The applications of perforated steel include:

Climate Control and Sun Protection

Perforated steel sheets are an excellent way of providing rooms with airflow and shade. They are often used as sun protection screens where ventilation is required. The porous nature of perforated steel allows the free movement of air. This results in substantial energy savings on ventilation, heating, and air conditioning.

Noise Reduction

Perforated steel sheets are often used for noise reduction in roof systems and walls. Perforated steel sheets can reduce the adverse effects of noise on workers’ health in noisy environments.

Balustrade Screening Panels

Perforated steel sheets are utilized in panels for stairways, balconies, and balustrade screens. They bring weather-resistant protection coupled with an attractive design.

Food and Beverage

Perforated steel is used for wine vats, drain dryers, sorting machines, fish farms, baking trays, and fruit and vegetable presses.

Chemical and Energy

Perforated steel is used for mine cages, battery separator plates, coal washing, centrifuges, gas purifiers, and filters.

Automotive

Perforated steel is used for radiator grilles, engine ventilation, running boards, motorcycle silencers, and oil filters.

Material Development

Perforated steel is used for textile printers, felt mills, glass reinforcement, cement slurry screens, and furnace screens.

Benefits of Perforated Steel

- Unique perforation patterns are available

- The tensile strength-to-weight ratio is high

- Economical

- Versatile

- Functional as well as aesthetic appeal

- Ventilation for light, air, gases, and sound

- Screening of fluids

- Pressure control or equalization

- Safety and Security

- Its cutting and fabrication are easy

Choosing the Right Perforated Steel Manufacturer

To ensure you have the most positive outcome when purchasing perforated steel from a perforated steel manufacturer, it is important to compare several companies using our directory or perforated steel manufacturers. Each perforated steel manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each perforated steel business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple perforated steel companies with the same form.

Broaching

Broaching CNC Machining

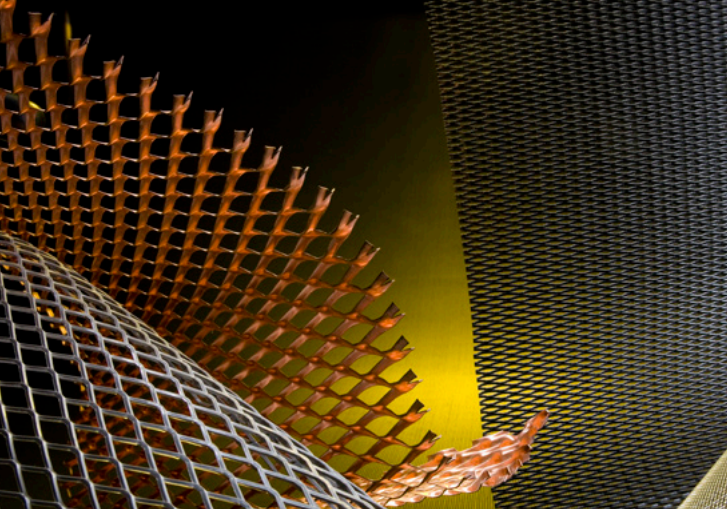

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

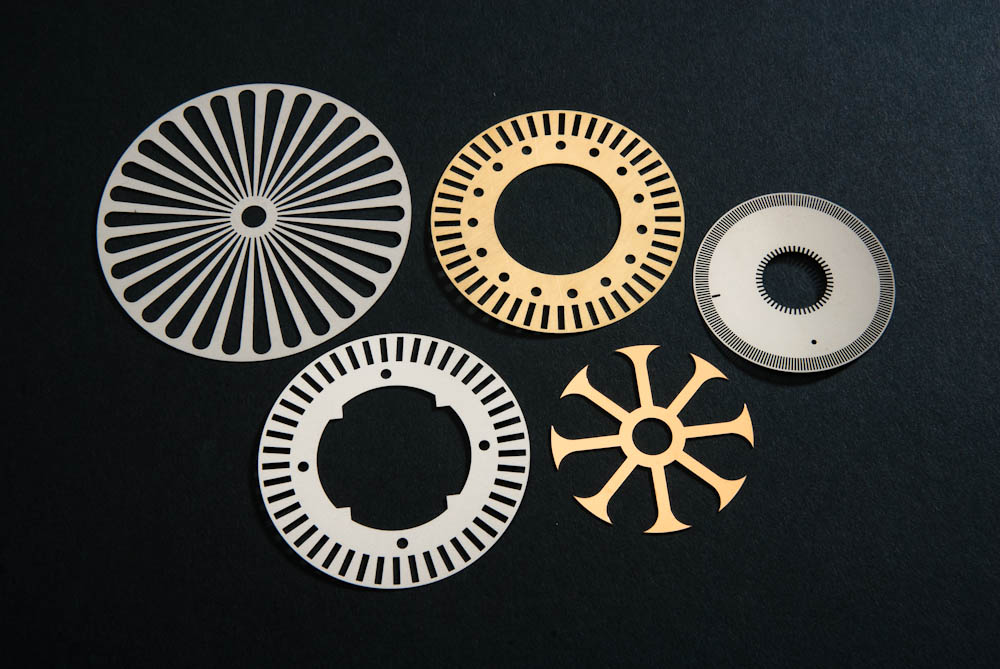

Metal Fabrication Perforated Metals

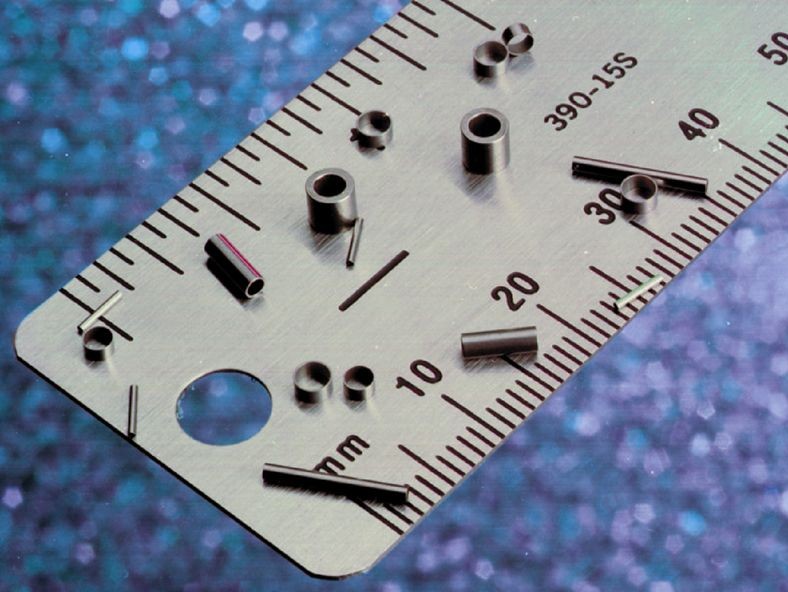

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

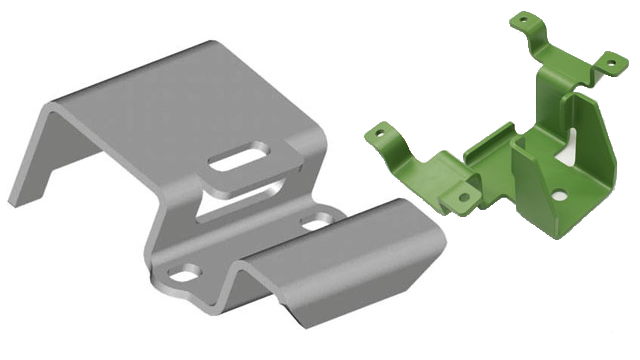

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services