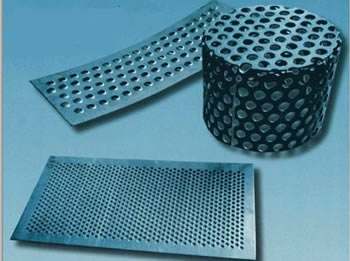

A perforated metal panel is a sheet of steel, copper, aluminum, brass, stainless steel, or zinc cut into thinner pieces with punctured holes. They also have shapes that have been cut out in a particular design. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Our commitment to excellence is reflected in the superior quality of our perforated metal products. We understand the diverse needs of our customers, and our extensive range of perforation patterns and materials ensures that we can meet and exceed expectations across various industries.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Metal Panel Manufacturers

What Is A Perforated Metal Panel?

The perforated metal panels can be made to any size and are used for decorative or functional architectural applications. They have a load-bearing capacity that is greater and more accurate. The perforated metal panels are used in the architectural, construction, interior decorating, chemical processing, aerospace, and cryogenic sectors. Besides enhancing the appearance of metals, the process of perforating has other useful results, such as noise suppression and protection.

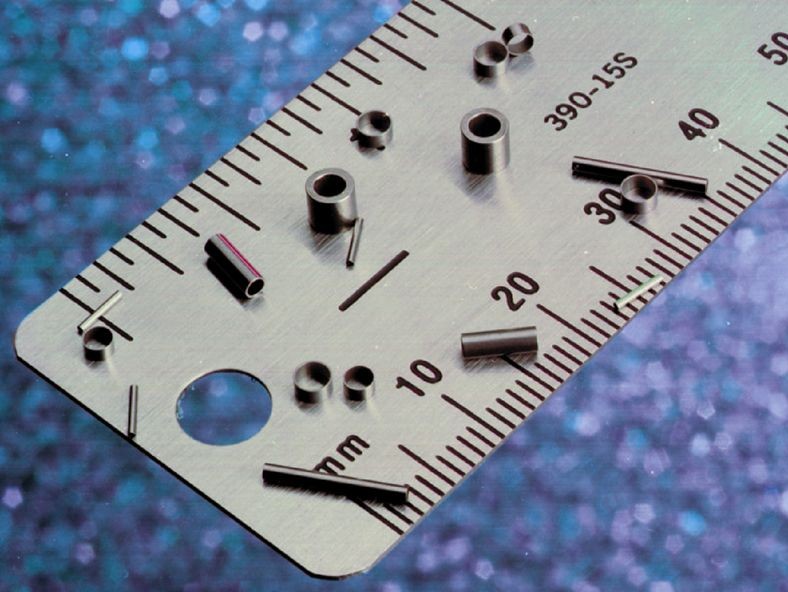

The metals’ size, the thickness of the gauge, types of materials, and their application affect the types of metals chosen for the metal perforation process. Round or slotted holes, squares, and hexagons are some of the shapes that can be produced.

How Perforated Metal Panels are Made

Perforated metals are made from large rolls of sheet metal. There are two different ways that the perforation process can be done. These two ways depend on the design and complexity of the punctures.

All-across punching presses produce simple, repetitive patterns extending across the entire sheet of metal. In this production, the sheet metal is placed through the press. In this press, rams in the shape of the design hit down on the metal. A different type of punching press is used to produce unique and complex designs. The outcomes from this process are used for decorative purposes.

Sectional punching presses are usually CNC controlled and transport the sheet of metal. This metal sheet is brought underneath a stationary punching ram to create an intricate pattern. As the first perforation process is finished, secondary processing can be made on the panels. This process is made to enhance temperature and corrosion resistance. A bath of molten zinc is usually used to galvanize the metal panels.

Protective coatings can be applied to provide a shiny finish. Besides this, it also leads to slow rusting and tarnishing of the metal panel. For more detail, panels can also be corrugated. This process bends the perforated metal panels into a uniform and continuous wave-like design.

Types of Perforated Metal Panels

Depending on the type of application, different types of metal can be used for perforation because some metals are more ductile, stronger, or more corrosion-resistant.

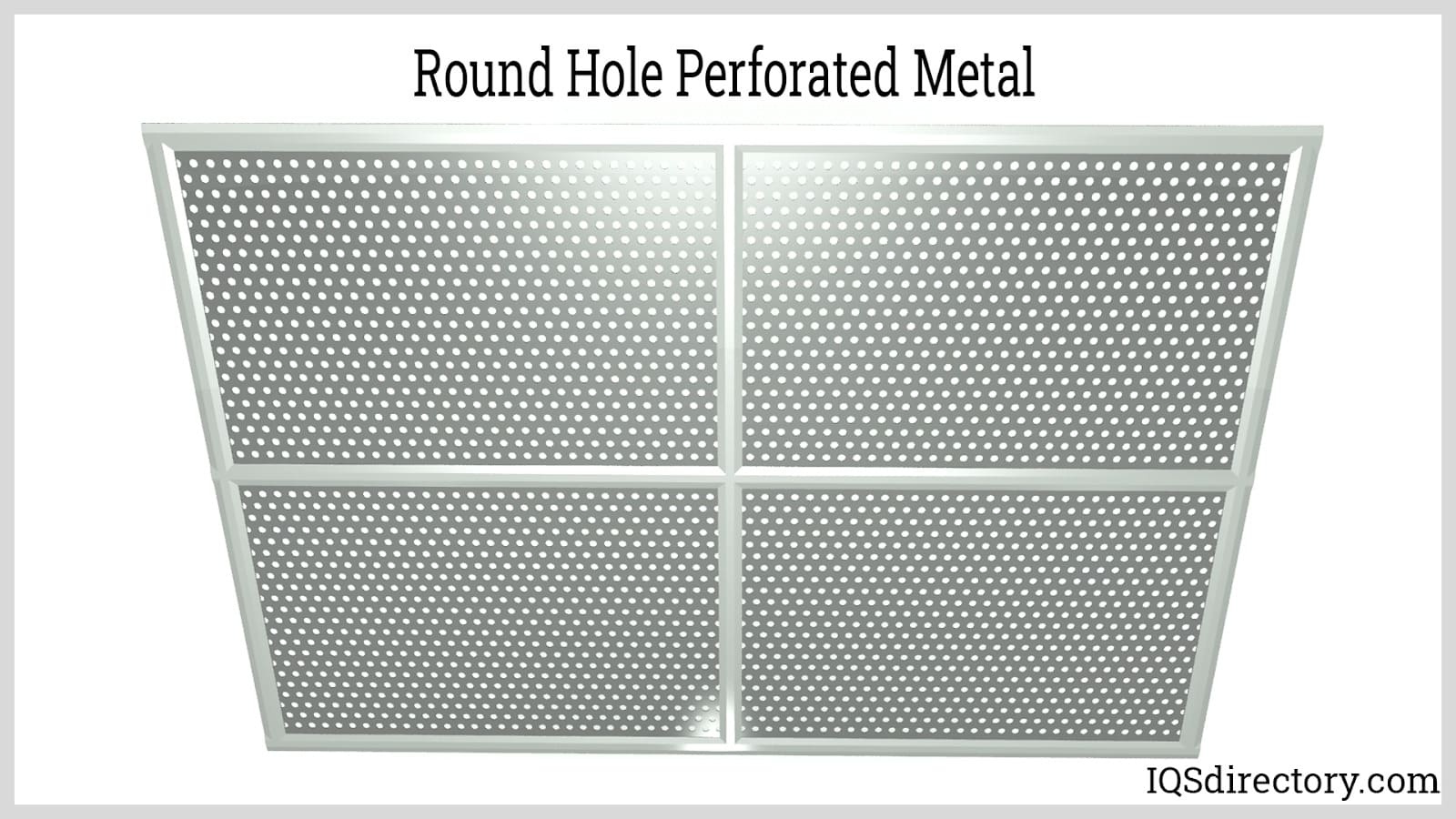

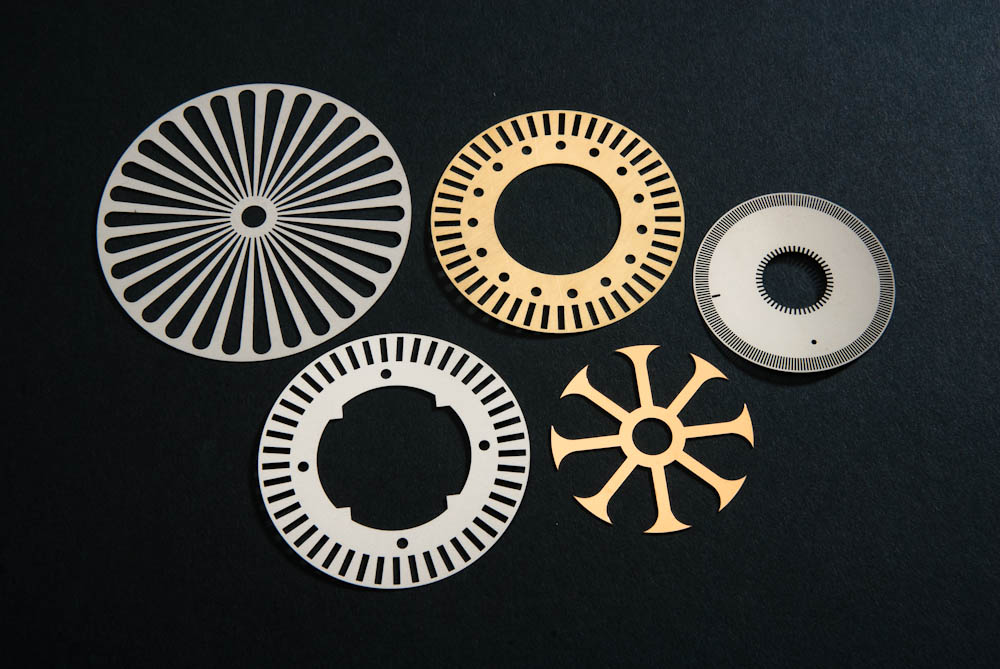

Round Hole Perforated Metals

Round hole perforated metals have patterns in two forms: staggered or straight lines. Staggered patterns result from the holes being out of order, whereas straight lines have holes placed perpendicular and parallel.

The end margins of the sheet margin come in three options: finished, blank, or unfinished. Finished margins are uniform and complete. Unfinished margins are not solid at the edge of the sheet. Finally, with blank margins, the holes that move towards the edge of the sheet are contained in round perforations.

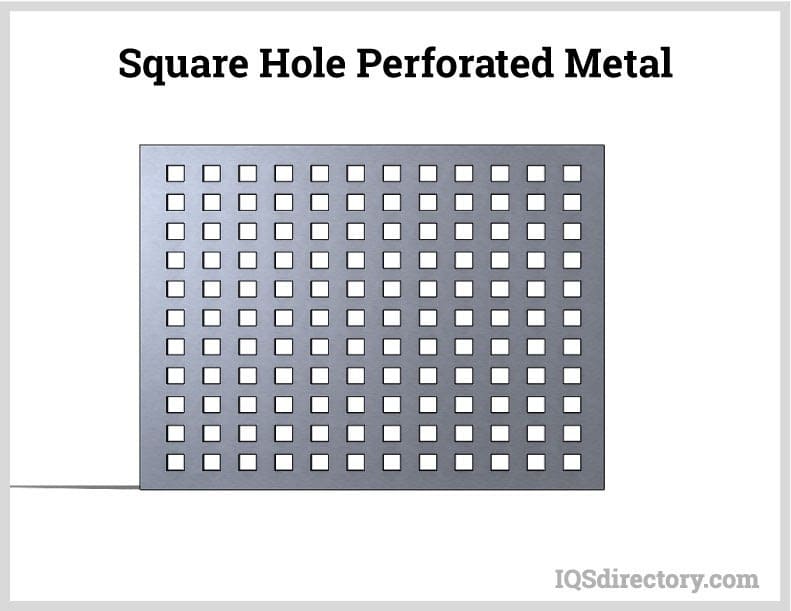

Square Hole Perforated Metals

Square holes in perforated metals contain a linear pattern that provides a modern appearance and results in a higher degree of open space. Many square hole perforated metals contain different hole designs and sizes.

Square hole perforated metals can also be found in staggered or straight line patterns.

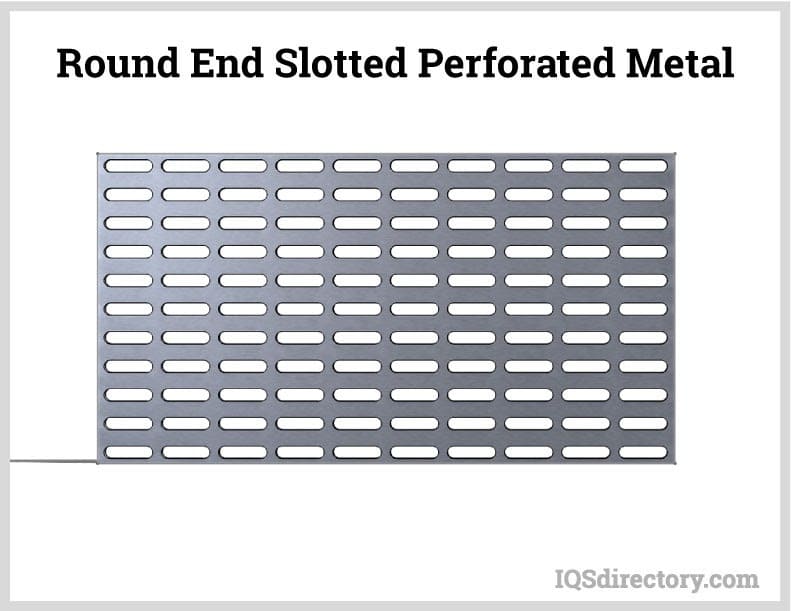

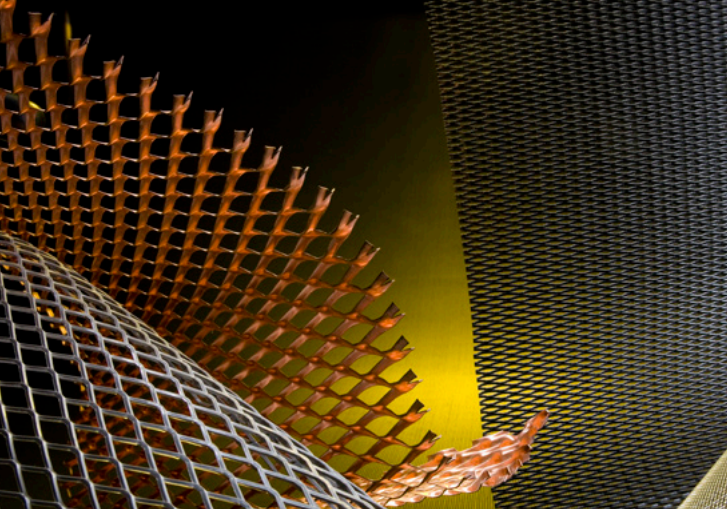

Slotted Perforated Metals

These perforated metals have elongated holes with round or square ends, either staggered or in straight lines. A slotted die is used to punch the holes for the slotted design.

This slotted pattern gives the perforated metals an extraordinary strength-to-weight ratio and allows other elements like light, air, liquid, and sound to pass through. The length and width of the holes can vary.

Applications and Uses of Perforated Metal Panels

Perforated metal panels are used in architecture, construction, interior decorating, chemical processing, aerospace, and cryogenics. The panels help in building insulation by giving structural support in building construction. For example, they act as infill panels underneath stairway handrails. They are added to walls, roofs, and other structural components for decorative purposes.

Choosing the Correct Perforated Metal Panel Supplier

To ensure you have the most productive outcome when purchasing perforated metal panels from a perforated metal panel supplier, it is important to compare several companies using our directory of metal panel suppliers. Each metal panel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each metal panel business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple perforated metal panel companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

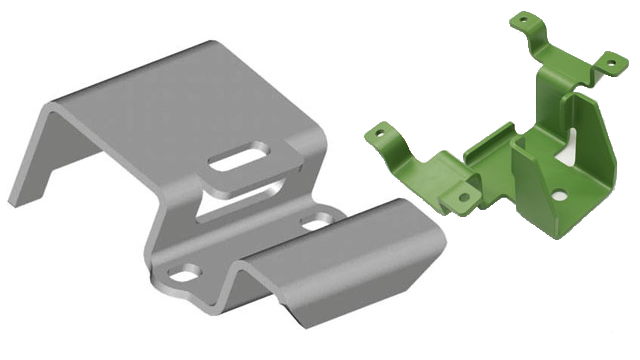

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services