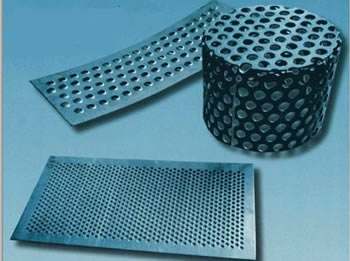

Aluminum with holes stamped or punched into it in a certain pattern or sequence using a machine, a tool, or a combination of these is known as perforated aluminum. Aluminum sheets can be perforated in several ways and with many different geometrical patterns and styles. Perforation is a flexible method used for various purposes and can offer gratifying answers for improving a structure’s aesthetic and functionality. Because it possesses many desired qualities, aluminum is widely used and frequently preferred over other metals as a raw material for producing perforated sheets. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Our commitment to excellence is reflected in the superior quality of our perforated metal products. We understand the diverse needs of our customers, and our extensive range of perforation patterns and materials ensures that we can meet and exceed expectations across various industries.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Aluminum Manufacturers

These attributes include durability, heat resistance, strength, corrosion resistance, rust resistance, and recyclability. Aluminum sheets with holes are visually appealing, but they also serve other purposes. They are a great way to screen out the light. In addition, perforated aluminum is often used as sound and noise suppressant to create a quieter and more comfortable working environment. The most common application for perforated aluminum as accent pieces is in the architectural field. Perforatedaluminum is used in several sectors, including acoustics, food and beverage, chemical, and energy, for purposes like fluid and proper filtration.

Creating Perforated Aluminum

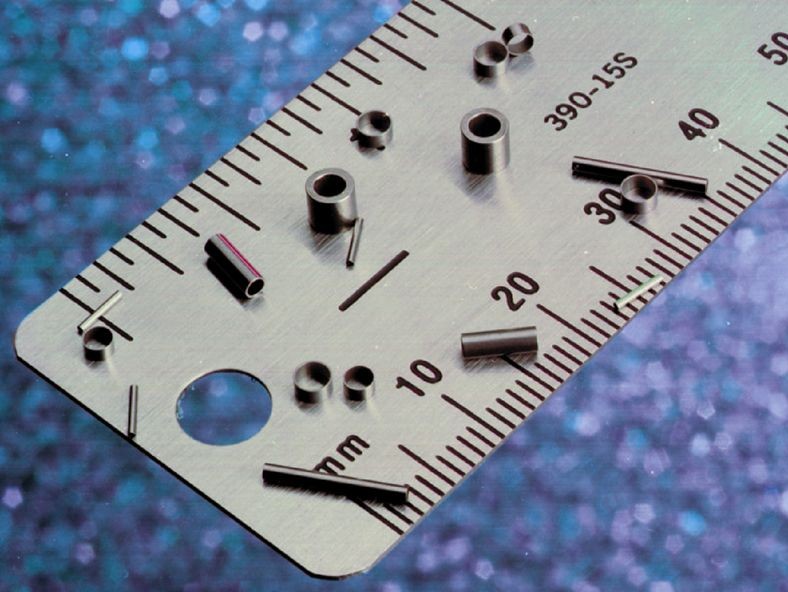

Aluminum can be perforated using a variety of techniques. The sheet metal that will be created, which is thin and flat and can be easily cut and bent, is a crucial component of the process. Gauges measure metal thickness, with higher numbers signifying thinner metals. The procedure is irrelevant as long as it creates the required holes in the metal sheets because perforated metals can have a variety of shapes punched or stamped into them. The processes of die and punch and needles on a roller are frequently used to create perforated aluminum.

Finishes for Perforated Aluminum

Anodized Aluminum

Anodized aluminum offers a high-quality cosmetic finish with high resistance to fading and is a good medium- to long-term solution for corrosion prevention. Anodizing is a translucent coating that is a part of the metal; it preserves and improves the properties of aluminum. Given that the perforated aluminum sheets will remain "dipped" in the tank for longer, anodizing with darker colors is more expensive.

Coating with Aluminum Powder

Coating with powder is an excellent medium- to long-term option with a nice aesthetic finish of perforated aluminum sheets. Powder-coating paints are now more fade-resistant because the formula has changed significantly over time. There are different "powder classes," with class 1 typically used for most architectural metalwork and class 2 typically used for high-weather facades.

Perforated Aluminum’s Benefits

- It is easily finished with a wide selection of color options for anodized or powder coatings.

- Its low weight makes it perfect for cladding and other architectural uses.

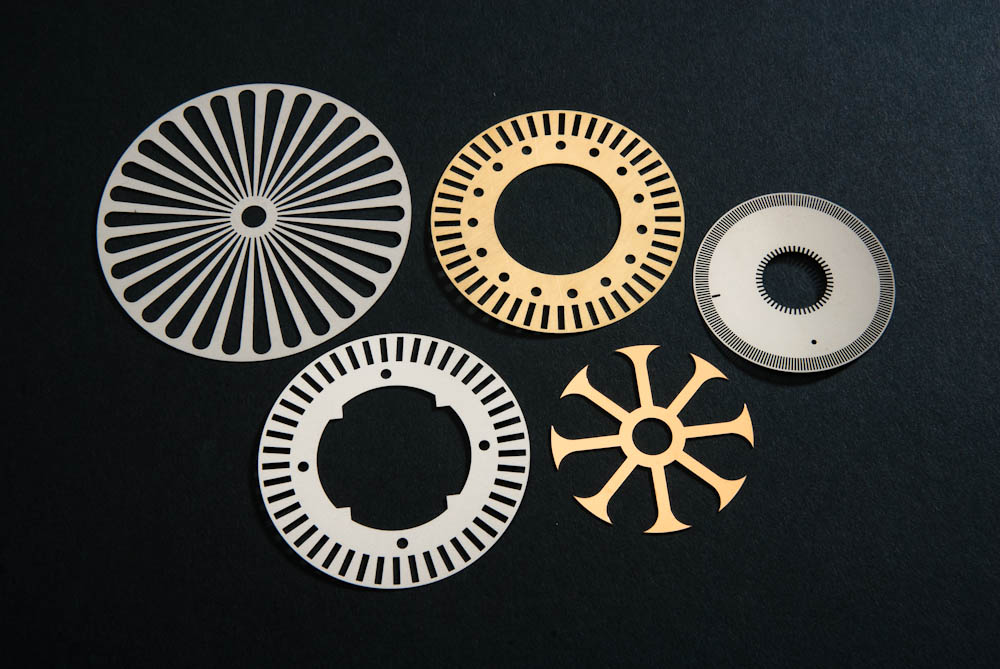

- the largest range of perforation designs, sizes, and forms

- perforated and easily formed

- Perforated aluminum sheets have a long lifespan because they are sturdy and resistant to corrosion.

- various grades of aluminum

- Through remelting, environmentally-friendly aluminum may be recycled repeatedly.

Applications of Perforated Aluminum

Architectural applications benefit greatly from the aesthetic appeal, easy fabrication, and formability of perforated aluminum sheets. If comparing the same sheet thickness, mild steel and stainless steel are stronger and more durable than aluminum; however, aluminum is almost three times lighter, making it an advantageous material for cladding, particularly if weight is an important issue.

Aluminum has a specific gravity of 2.75 kilos, whereas mild and stainless steel has a specific gravity of about 8 kilos per square meter with a 1mm thickness. The weight of perforated aluminum sheets is further reduced, making it the perfect material for ventilation panels, cladding panels, and ceiling tiles where a minimum weight is required. Perforated aluminum sheets are simple to make, cut, roll, and fold.

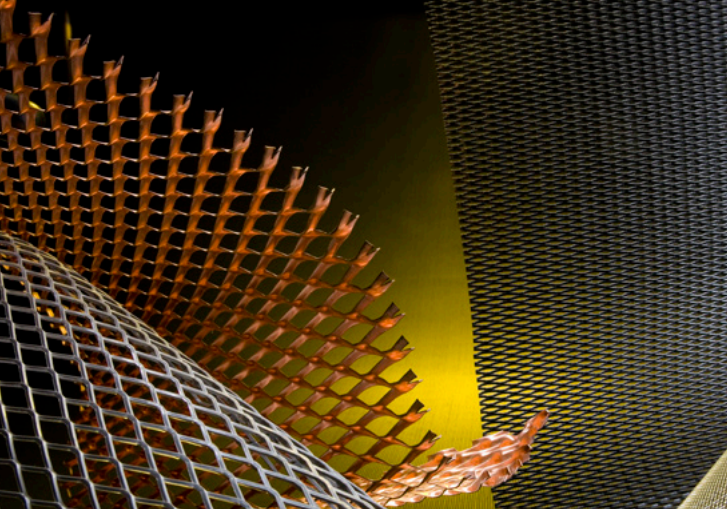

Generally, perforated aluminum sheets are extremely well-liked in the architectural, food and beverage, chemical and energy, automotive, furniture, filtration, HVAC, sound system, construction, and material development industries. They are sold for use in various parts and products.

Perforated aluminum is used for a variety of things, including speaker covers, acoustic panels, industrial cabinetry, cheese graters, spoons, colanders, ladles, water and coffee screens, cement slurry screens, cinder screens, blast furnace screens, drain coverings, pipe guards, ventilation grilles, air filters, oil filters, retail displays, indoor and outdoor furniture, decorative wall paneling, and architectural details.

Choosing the Correct Perforated Aluminum Manufacturer

To ensure the most constructive outcome when purchasing perforated aluminum from a perforated aluminum manufacturer, it is important to compare several companies using our directory of perforated aluminum manufacturers. Each perforated aluminum manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each perforated aluminum business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple perforated aluminum companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services