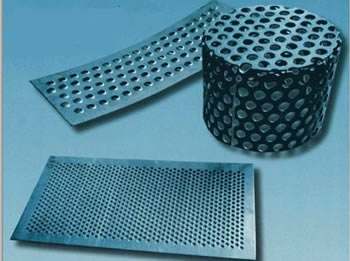

Perforated steel is a steel sheet stamped or punched with a machine to create a pattern of holes. Perforated steel can also be called a perforated plate, perforated sheet, or perforated screen. Perforated steel was developed for the mining industry for use in the filtering of coal. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Steel Manufacturers

How Perforated Steel is Made

Perforated steel, also known as perforated sheet metal or punched steel, is a versatile engineering material produced through various precision processes. The manufacturing journey starts with a high-quality steel sheet, such as stainless steel, galvanized steel, or carbon steel, depending on the intended application. The process by which the steel is perforated determines the pattern, hole size, strength, and finish of the final product, making it crucial for industries to select the right perforation method for their needs.

One of the most common and cost-effective manufacturing methods is the use of a rotary pinned perforation roller. This process involves passing the steel sheet beneath a large, cylindrical roller embedded with sharp-pointed needles. As the roller rotates continuously, it punches precise holes throughout the sheet. The roller can be equipped with a variety of needle sizes and patterns, enabling the creation of standard or customized perforation designs. In some cases, these needles are heated, allowing them to melt the metal simultaneously, which creates a reinforced ring around each perforation. This feature is especially important for applications demanding enhanced durability or strength at the hole edges, such as architectural cladding or industrial screening.

Another widely adopted technique is die and punch perforating. During this process, a sheet outfitted with needles is repeatedly pressed onto the moving steel, systematically punching holes in a precise layout. The leftover metal, known as scrap or slug, is sheared off, and the sheet is then smoothed to remove any sharp edges. Die and punch perforating stands out for its efficiency and scalability, making it suitable for large-scale production runs where uniformity and speed are priorities—such as manufacturing automotive components, air diffusers, or industrial filters.

For applications where the highest level of precision and customization is required, manufacturers turn to laser perforation technology. In this advanced process, a focused laser beam is used to melt or vaporize the steel, creating holes with impeccable accuracy and minimal burrs. Laser perforation offers exceptional control over hole size, pattern, and spacing, allowing for complex designs that are difficult to achieve with traditional mechanical methods. While this process is more expensive due to equipment and energy requirements, it is ideal for high-performance architectural features, custom decorative panels, and specialized filtration systems demanding tight tolerances.

Quality Assurance in Perforated Steel Production

During and after the perforation process, rigorous quality control checks are performed. These include measuring hole diameter, inspecting alignment, ensuring pattern consistency, and checking for surface defects. Manufacturers may also apply surface treatments, such as powder coating, anodizing, or galvanization, to enhance corrosion resistance, aesthetics, or functional properties based on the end-use environment. By investing in modern production technology and strict quality assurance, reputable perforated steel suppliers deliver sheets that meet or exceed international standards and customer specifications.

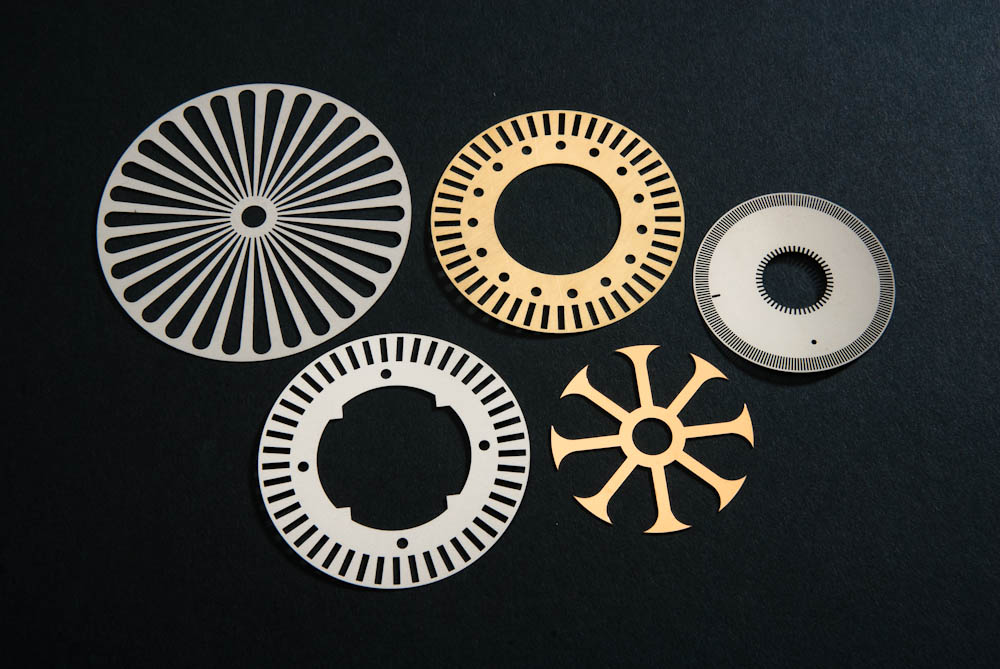

Types of Perforated Steel

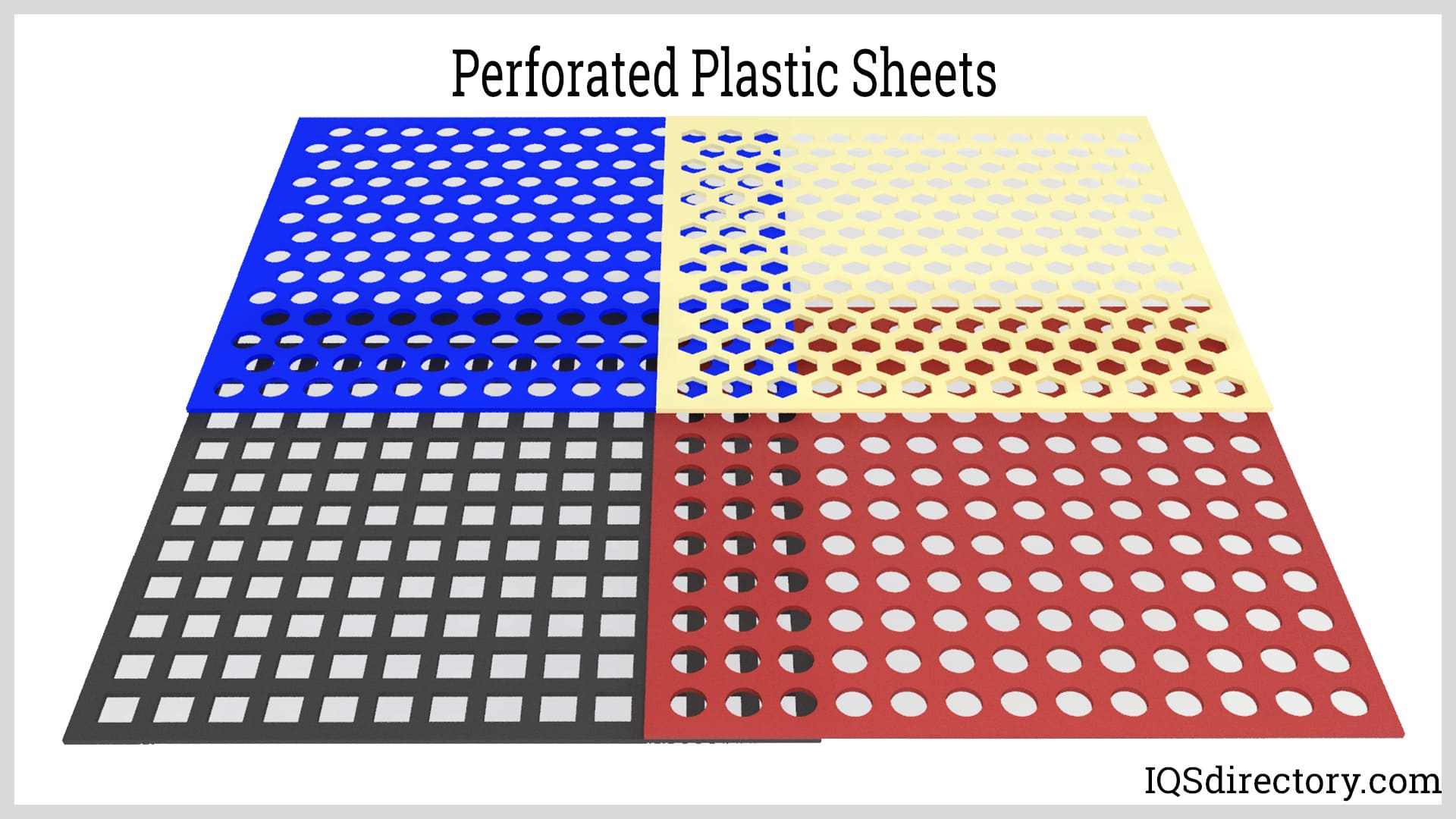

Perforated steel is available in a wide array of hole shapes, patterns, and materials, each engineered for specific structural, functional, or decorative purposes. Understanding the available types is essential for architects, engineers, and buyers aiming to select the optimal product for their project or industrial application.

Round Hole Perforated Steel

Round hole perforated steel is the industry standard and the most popular choice due to its versatility, cost-effectiveness, and ease of fabrication. Manufactured by punching uniformly sized round holes into a steel sheet, this type is ideal for applications requiring efficient airflow, light diffusion, or sound attenuation. Common uses include HVAC system components, acoustic panels, machine guards, and interior design elements such as feature walls or ceiling tiles. Its straightforward pattern ensures high open area percentages, making it suitable for filtration and ventilation systems where unrestricted airflow is critical.

Square Hole Perforated Steel

Square hole perforated steel features a grid of square-shaped holes, providing a modern and aesthetically pleasing look while maintaining excellent strength-to-weight ratios. The larger open area offered by square holes makes this type a go-to solution for protective enclosures, machine guards, speaker grilles, and architectural screening. The geometric precision of square perforations also lends itself well to applications where uniformity in light transmission or visual privacy is desired. Architects and designers often specify this product for building facades, sunshades, or privacy panels due to its striking appearance and robust performance.

Rectangle Slot Perforated Steel

Rectangle slot perforated steel is characterized by elongated slots rather than round or square holes. This configuration allows for increased open area and directional strength, making it especially well-suited for screening, filtering, and separation processes. It is frequently found in agricultural equipment, mining screens, food processing, and water treatment facilities. Additionally, its linear pattern is often used for modern architectural accents, lighting diffusers, and stair treads. The shape and orientation of slots can be customized to optimize material flow or visual effect based on project requirements.

Hexagonal Hole Perforated Steel

Hexagonal hole perforated steel stands out for its distinctive honeycomb pattern, which delivers both high open area and exceptional load-bearing strength. This unique combination makes hexagonal perforations popular in both industrial and architectural contexts. Typical applications include partitions, sunscreens, security panels, and decorative elements. The honeycomb structure is not only visually engaging but also offers efficient airflow and sound absorption, making it a preferred choice for modern commercial and public spaces seeking a balance between aesthetics and functionality.

Custom and Specialty Perforated Steel

In addition to the standard shapes, many manufacturers offer custom perforated steel solutions tailored to unique project needs. This includes intricate patterns, variable hole sizes, and material grades engineered for extreme environments or niche applications. Custom perforation is frequently used in branding, signage, lighting installations, and high-performance filtration systems. If you’re seeking a solution for a complex challenge, consult with a perforated steel supplier about custom design and fabrication options.

Applications of Perforated Steel

Thanks to its adaptability, durability, and visual appeal, perforated steel is deployed across diverse industries. Below are some of the most common and high-value applications, each highlighting how perforated metal solutions improve performance, safety, and aesthetics.

Climate Control and Sun Protection

Perforated steel sheets are an excellent choice for regulating airflow, temperature, and light within buildings. They are often installed as sun protection screens or ventilated facades, providing natural ventilation while minimizing solar gain. This energy-efficient approach reduces reliance on HVAC systems, resulting in lower energy consumption and improved occupant comfort. Architects frequently use perforated metal panels for shading devices in sustainable building designs.

Noise Reduction and Acoustic Control

Because of their ability to diffuse sound waves, perforated steel sheets are widely used in acoustic engineering. They serve as noise barriers in industrial plants, transportation infrastructure (such as highway sound walls), and commercial buildings. The perforations allow for the integration of sound-absorbing materials behind the panels, significantly reducing reverberation and improving the acoustic environment. This benefits worker health and productivity in noisy settings, such as factories, airports, and concert venues.

Balustrade Screening and Safety Panels

Perforated steel is a preferred material for stairway panels, balcony railings, and balustrade screens. Its inherent strength, corrosion resistance (especially when galvanized or made from stainless steel), and customizable appearance ensure long-lasting safety and visual appeal. In public spaces and high-traffic areas, perforated steel panels also provide weather resistance and comply with safety regulations while contributing to the overall aesthetic of the structure.

Food and Beverage Processing

Perforated steel plays a crucial role in food and beverage manufacturing. It is used in wine vats for drainage, baking trays for even heat distribution, sorting machines, fish farming enclosures, and fruit and vegetable presses. Stainless steel perforated sheets are especially valued for their sanitary properties, easy cleaning, and compliance with food safety standards. If you’re searching for hygienic and efficient equipment, explore perforated steel solutions for the food industry.

Chemical Processing and Energy Sector

The chemical and energy industries rely on perforated steel for a variety of functions, including battery separator plates, mine cages, coal washing screens, centrifuge components, gas purifiers, and industrial filters. These applications demand materials that can withstand harsh chemicals, high pressures, and extreme temperatures. Selecting the right steel grade and perforation pattern is essential for optimizing filtration efficiency, safety, and equipment lifespan.

Automotive and Transportation

In the automotive sector, perforated steel is used for radiator grilles, engine ventilation panels, running boards, oil filters, and motorcycle silencers. The material’s lightweight yet strong nature helps reduce vehicle weight, improve fuel efficiency, and enhance safety. Perforated steel is also used in transportation infrastructure for noise barriers, walkway surfaces, and station facades. Looking for automotive-grade perforated metal? Contact a supplier for specification guidance.

Material Development and Industrial Manufacturing

Perforated steel is indispensable in material processing and industrial manufacturing. It is widely used in textile printers, felt mills, cement slurry screens, glass reinforcement, and furnace components. Its ability to be tailored for specific filtration, reinforcement, or separation tasks makes it a valuable asset in a wide range of production environments.

Architectural and Decorative Applications

Modern architects and designers embrace perforated steel for its blend of form and function. Decorative screens, façade cladding, art installations, and branded signage all benefit from perforated steel’s customizable patterns, durability, and weather resistance. Its use in interior design—such as ceiling tiles, feature walls, and lighting diffusers—adds a contemporary flair while providing practical benefits like light diffusion and acoustic dampening.

Benefits of Perforated Steel

- Wide selection of unique perforation patterns to match functional or decorative requirements

- High tensile strength-to-weight ratio for efficient structural performance

- Cost-effective and economical for large and small projects

- Versatile material: suitable for industrial, commercial, and architectural uses

- Combines functional performance with aesthetic appeal for creative design possibilities

- Enables controlled ventilation for light, air, gases, and sound—critical for HVAC, acoustic, and safety applications

- Facilitates precise screening and filtration of fluids and solids

- Allows for effective pressure control and equalization in technical systems

- Enhances safety and security by serving as barriers, guards, or protective enclosures

- Easy to cut, fabricate, and install—reducing labor costs and project timelines

- Customizable finishes (galvanized, powder-coated, anodized) for improved corrosion resistance and appearance

- Eco-friendly: steel is recyclable, supporting green building and sustainability initiatives

Key Decision Factors When Selecting Perforated Steel

Choosing the right perforated steel product involves evaluating several important criteria:

- Material type and grade: Stainless steel, carbon steel, galvanized steel, aluminum—each offers unique properties for durability, corrosion resistance, and strength.

- Hole size, shape, and pattern: These affect airflow, filtration efficiency, structural integrity, and visual impact.

- Sheet thickness and dimensions: Must be matched to load requirements and installation constraints.

- Surface finish and treatment: Powder coating, painting, or galvanization to meet corrosion and aesthetic needs.

- Compliance and standards: Ensure the product meets relevant industry regulations (ASTM, ISO, etc.).

- Customization requirements: Consider whether you need bespoke patterns, branding, or fabrication services.

Frequently Asked Questions About Perforated Steel

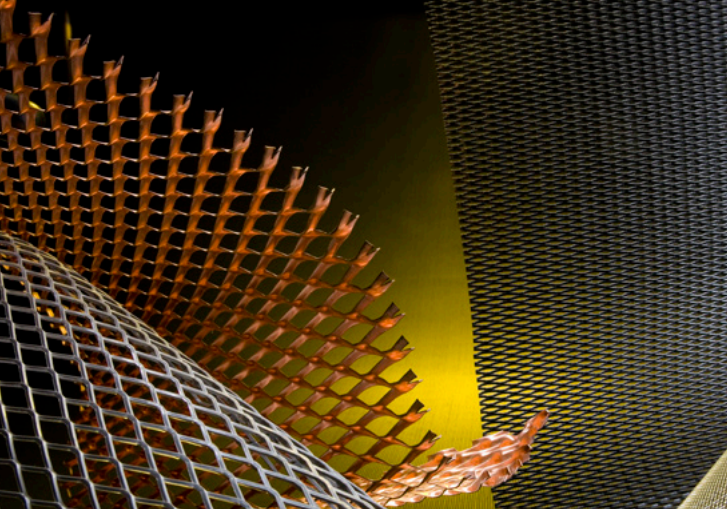

- What is the difference between perforated steel and expanded metal? Perforated steel is produced by punching or laser-cutting holes in a solid sheet, while expanded metal is made by stretching and slitting the sheet to create a mesh without material loss. Each has distinct applications and structural properties.

- How do I choose the right perforation pattern? Consider the desired open area, airflow, strength, and appearance. For technical advice, contact a perforated steel expert.

- Can perforated steel be painted or coated? Yes, it can be powder-coated, painted, or galvanized for enhanced corrosion resistance and color customization.

- Is perforated steel suitable for outdoor use? When properly finished, perforated steel resists rust and weathering, making it ideal for exterior facades, fences, and screens.

- What is the maximum sheet size available? Standard sheet sizes vary by supplier, but custom sizes and formats are often available. Inquire with your manufacturer for project-specific options.

- How do I maintain perforated steel panels? Routine cleaning and inspections will ensure long-term performance. For high-exposure environments, select corrosion-resistant grades and finishes.

Choosing the Right Perforated Steel Manufacturer

Securing the highest quality perforated steel products requires partnering with a reputable, experienced manufacturer or supplier. To ensure a successful buying experience, follow these best practices:

- Research several perforated steel manufacturers using a comprehensive online directory. Compare their capabilities, certifications, and product offerings.

- Examine each manufacturer’s business profile page to understand their specialization—such as architectural, industrial, or custom fabrication expertise.

- Use direct contact forms to request detailed information, technical datasheets, or custom quotes tailored to your project’s requirements.

- Leverage proprietary website preview tools to quickly assess each company’s production technology, lead times, and service quality.

- Submit a single Request for Quote (RFQ) form to reach multiple suppliers, streamlining your procurement process.

- Check for customer reviews, case studies, and past project portfolios to gauge reliability and performance.

- Ask about value-added services such as design assistance, prototyping, on-site measurement, and installation support.

Ready to start your project? Find a trusted perforated steel supplier or request a quote today to receive competitive offers tailored to your specifications and timeline.

Need Help Specifying Perforated Steel?

If you’re unsure which perforated steel product best fits your needs, consider these common search prompts:

- What perforated steel sheet is best for exterior building facades?

- How do I select a corrosion-resistant perforated metal for marine environments?

- Which perforation pattern offers the best sound absorption for acoustic panels?

- What is the difference between stainless steel and galvanized perforated sheets?

- Where can I find custom perforated metal fabrication services near me?

For answers to these questions and more, contact a perforated steel expert or browse our resource library for detailed guides and industry insights.

Conclusion: The Value of Perforated Steel

Perforated steel stands at the intersection of strength, style, and functionality. From industrial machinery and architectural facades to acoustic engineering and sustainable building, this versatile material delivers unmatched performance and design freedom. By understanding the various manufacturing methods, material choices, and application possibilities, you can confidently specify the right perforated steel solution for your next project. For technical support, product comparisons, or procurement assistance, connect with leading perforated steel suppliers and unlock the full potential of perforated metal engineering today.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

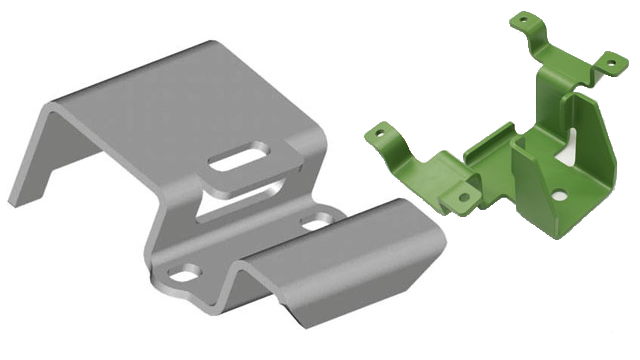

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

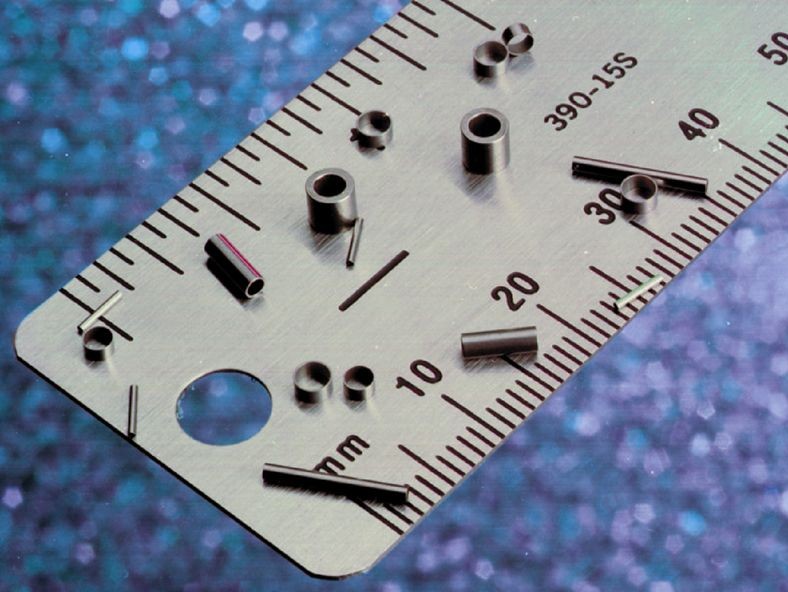

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services