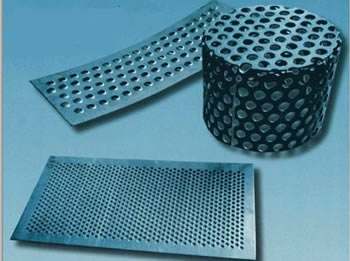

A perforated metal panel is a sheet of steel, copper, aluminum, brass, stainless steel, or zinc cut into thinner pieces with punctured holes. They also have shapes that have been cut out in a particular design. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Metal Panel Manufacturers

What Is a Perforated Metal Panel?

Perforated metal panels are versatile architectural and industrial materials manufactured by puncturing sheet metal with a variety of hole patterns. These panels can be custom fabricated to any size or specification, making them a preferred choice for both decorative and functional applications. Perforated metal panels are recognized for their superior load-bearing capacity, precision engineering, and adaptability to a broad range of environments.

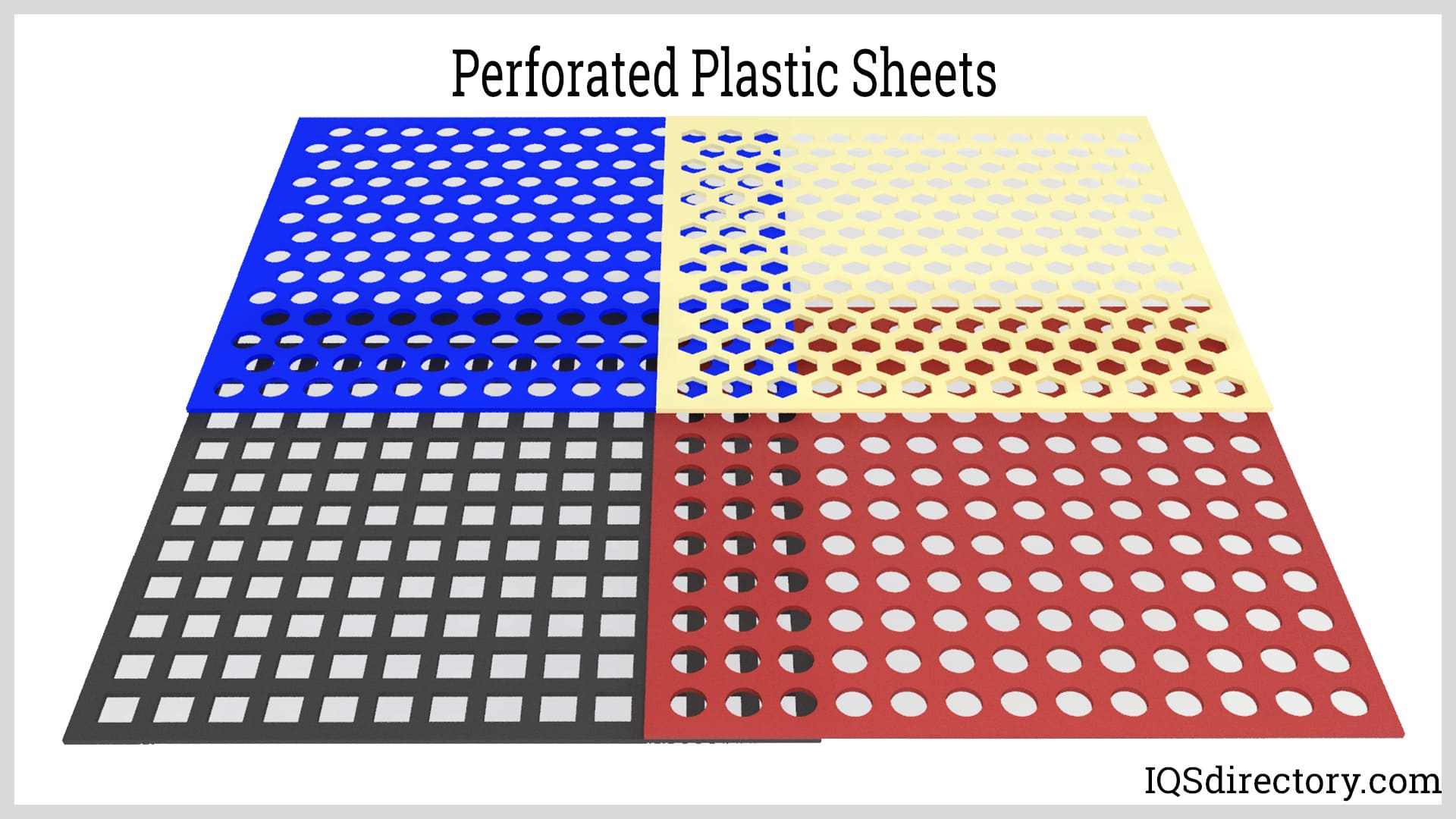

The selection of metal—including stainless steel, aluminum, galvanized steel, copper, and brass—depends on factors such as panel thickness, desired strength, corrosion resistance, and intended application. Perforation patterns vary in shape, including round, square, slotted, and hexagonal holes, each offering distinct structural and aesthetic benefits. In addition to enhancing the visual appeal of metal surfaces, the perforation process delivers practical results such as acoustic dampening, improved ventilation, light filtration, and enhanced safety and protection.

Key Features of Perforated Metal Panels

- Customizable hole shapes and patterns for tailored architectural design

- Available in a wide range of materials and finishes

- Excellent strength-to-weight ratio for structural support

- Corrosion resistance and durability in harsh environments

- Energy efficiency and acoustic performance improvements

- Applications in commercial, industrial, and residential projects

Looking for specific perforated metal panel solutions?

Explore our comprehensive guide below to learn more about manufacturing processes, material selection, use cases, benefits, and how to choose the right supplier for your project. If you have a unique design in mind or need technical assistance, contact a trusted perforated metal panel supplier or read our FAQs for more information.

How Perforated Metal Panels Are Made

Perforated metals are produced from coils or sheets using specialized punching and stamping machinery. The manufacturing process is determined by the complexity of the pattern, the thickness of the metal, and the intended use of the panels. Understanding how these panels are fabricated helps buyers make informed decisions regarding quality, customization, and application suitability.

Punching and Stamping Methods

Two primary perforation techniques are widely used in the industry:

- All-Across Punching Presses: Ideal for high-volume production of simple, repetitive perforation patterns that extend across the entire metal sheet. Rams shaped in the desired pattern punch down on the sheet, enabling efficient processing of large quantities.

- Sectional (CNC-Controlled) Punching Presses: Used for creating intricate, custom, or decorative designs. The sheet is moved under a stationary punching ram, often controlled by CNC (Computer Numerical Control) systems to ensure precise and repeatable results. This technique enables architects and engineers to realize complex geometric patterns and branding elements.

Secondary Processing and Finishing

Once perforation is complete, panels may undergo secondary processes to enhance performance and longevity:

- Galvanizing: Immersing panels in molten zinc to provide a corrosion-resistant coating, ideal for exterior and industrial applications.

- Powder Coating & Anodizing: Applying protective and decorative finishes for increased durability, color variety, and resistance to wear and fading.

- Corrugation: Bending panels into wave-like shapes to increase rigidity, improve aesthetics, and support load-bearing applications.

- Deburring & Polishing: Smoothing edges and surfaces for safety and a premium appearance, particularly important for interior and decorative uses.

These finishing options allow perforated metal panels to meet strict industry standards for safety, performance, and design.

Types of Perforated Metal Panels

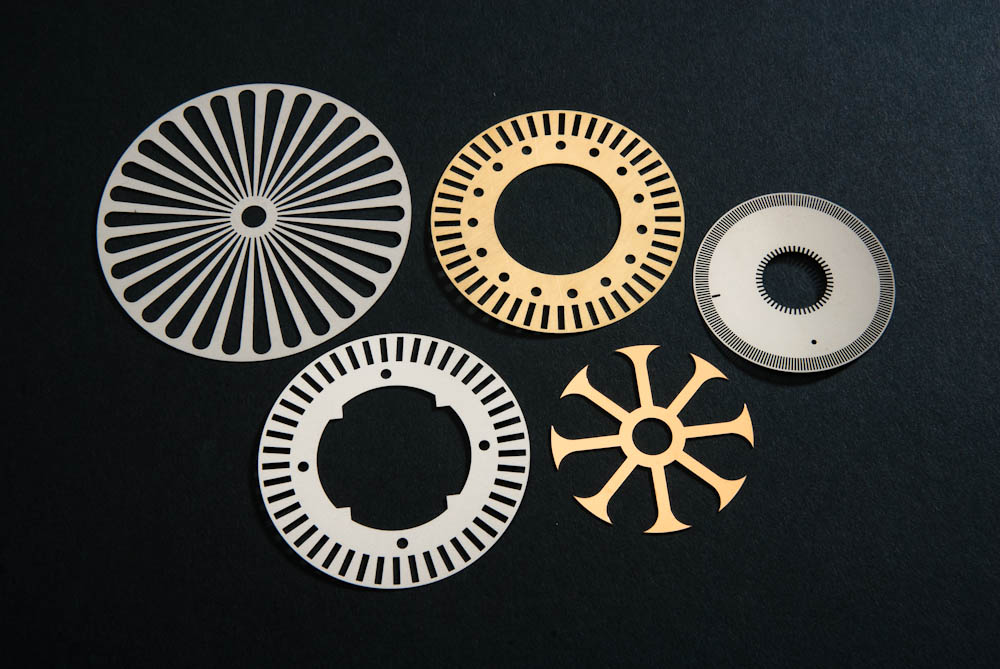

The wide variety of perforated metal panel types allows for tailored solutions across architectural, industrial, and commercial projects. The choice of perforation shape, pattern, and metal type is influenced by intended use, performance requirements, and aesthetic preferences. Here are the most common types found in the market:

Round Hole Perforated Metals

Round hole perforated metals are the most popular panel type in the industry, prized for their versatility, efficient material usage, and superior strength. Patterns are available in staggered (offset) or straight line configurations. Staggered patterns provide optimal structural integrity and better open area, while straight line patterns deliver a more uniform appearance, often preferred for contemporary interior and exterior design projects.

Margins of round hole panels can be finished, unfinished, or blank—each offering different edge treatments for installation flexibility and visual refinement. Finished margins ensure a neat, solid border, while unfinished or blank margins allow holes to extend to the sheet’s edge for seamless integration into larger assemblies.

- Best for: Acoustic panels, sunshades, infill panels, screening, filtration, and ventilation grills.

- Available materials: Aluminum, stainless steel, galvanized steel, brass, copper, and more.

Searching for round hole perforated metal for your project? Explore supplier options or see common use cases below.

Square Hole Perforated Metals

Square hole perforated metals feature a modern, geometric look with linear patterns that provide a high degree of open area. These panels are ideal for applications requiring maximum airflow or visibility, like security screens and ventilation panels. Square hole designs are also available in various sizes and layouts—including staggered and straight alignments—to meet diverse architectural and industrial requirements.

- Best for: Machine guards, balustrades, partitions, fencing, screening, and retail displays.

- Benefits: Modern appearance, high visibility, excellent ventilation, and easy cleaning.

Slotted Perforated Metals

Slotted perforated metals have elongated holes (slots) with either rounded or square ends. These can be arranged in straight or staggered lines, depending on structural and design needs. The distinctive slotted pattern provides an excellent strength-to-weight ratio and enables controlled passage of air, light, liquids, or sound—making them a top choice for filtration, noise reduction, and light diffusion applications.

- Best for: Acoustic baffles, air diffusers, sieves, guards, filters, and lighting fixtures.

- Benefits: Customizable slot dimensions, superior airflow, efficient drainage, and unique visual effects.

Other Specialty Perforation Patterns

Beyond round, square, and slotted holes, manufacturers offer a wide array of custom and decorative patterns, such as hexagonal, diamond, oblong, and bespoke geometric shapes. These specialty options enable architects and designers to achieve signature facades, branded elements, or functional surfaces tailored to unique project requirements.

- Hexagonal perforated panels for maximum open area and honeycomb aesthetics

- Decorative patterns for artistic cladding, feature walls, and signage

- Custom logo perforations for branding in retail, hospitality, and corporate environments

Applications and Uses of Perforated Metal Panels

Perforated metal panels are chosen for their unique blend of strength, functionality, and design flexibility. Their applications span a variety of industries, with new uses emerging as technology and design trends evolve. Here are some of the most common and high-value uses:

- Architectural Cladding: Enhance building facades with visually striking, functional exteriors that deliver solar shading, privacy, and weather protection.

- Interior Design: Create room dividers, ceiling panels, feature walls, and custom lighting with tailored patterns and finishes.

- Acoustic Solutions: Reduce noise pollution in offices, theaters, and public spaces using perforated acoustic panels with sound-absorbing backing.

- Ventilation & Airflow Control: Facilitate efficient air movement in HVAC systems, equipment enclosures, and data centers.

- Screening & Privacy: Provide privacy barriers for balconies, stairwells, and parking garages without sacrificing aesthetics or airflow.

- Filtration & Sieving: Utilize precision-perforated metal for separating solids, liquids, or gases in industrial and processing environments.

- Safety & Protection: Employ as guards, machine covers, or anti-slip flooring for workplace safety and compliance.

- Sunshades & Louvers: Reduce solar heat gain and glare in commercial and residential buildings.

- Signage & Branding: Incorporate custom patterns and logos for unique architectural statements and wayfinding.

Industry-Specific Applications

- Construction: Facades, infill panels, security fencing, stair treads

- Transportation: Grilles, noise barriers, vehicle interiors

- Food Processing: Filters, trays, drying racks

- Energy: Windbreaks, battery enclosures, oil & gas filtration

- Aerospace & Defense: Lightweight panels, shielding, heat dissipation

- Chemical & Cryogenic: Corrosion-resistant filtration and containment

Want to see real-world examples? Browse case studies or ask about custom solutions for your industry.

Benefits of Using Perforated Metal Panels

Perforated metal panels offer a unique combination of technical and aesthetic benefits, making them a preferred material for architects, engineers, and facility managers alike. Here are the top reasons to consider perforated metal panels for your next project:

- Strength & Durability: Robust enough for structural support yet lightweight for easy installation and reduced building loads.

- Customization: Nearly unlimited design possibilities with adjustable hole sizes, shapes, open area ratios, and finishes.

- Corrosion Resistance: Materials and coatings are selected to withstand harsh outdoor or industrial environments.

- Acoustic Performance: Perforations combined with acoustic backings help absorb and diffuse sound, improving indoor comfort.

- Ventilation & Light Transmission: Enable controlled airflow and natural lighting, enhancing energy efficiency and comfort.

- Low Maintenance: Easy to clean, with finishes that resist dirt, graffiti, and weathering.

- Sustainability: Many panels are recyclable and can contribute to LEED credits and green building certifications.

- Safety: Used for anti-slip flooring, guards, and barriers to comply with safety codes and reduce workplace hazards.

- Value: Long service life and reduced lifecycle costs compared to alternative materials.

How to Choose the Right Perforated Metal Panel

Selecting the optimal perforated metal panel involves considering a range of factors including performance requirements, cost, aesthetics, and environmental conditions. Here’s a step-by-step guide to help buyers, architects, and engineers make informed choices:

- Define the Application: Will the panel be used for structural support, decoration, safety, or a combination of functions?

- Choose the Right Material: Consider durability, corrosion resistance, weight, and cost. Stainless steel and aluminum are popular for exterior use; galvanized steel offers cost-effective strength; brass and copper add decorative appeal.

- Select Hole Pattern and Size: Align open area and hole shape with goals for airflow, light, sound, and aesthetics.

- Specify Thickness and Size: Thicker panels offer greater strength, while larger panels reduce seams and installation time.

- Evaluate Finishes and Coatings: Choose powder coating, anodizing, or galvanizing for added protection and custom color options.

- Assess Compliance and Standards: Ensure panels meet relevant codes for fire safety, load bearing, and environmental exposure.

Need expert guidance? Contact a perforated metal panel supplier or get answers to common questions below.

Choosing the Correct Perforated Metal Panel Supplier

Your choice of supplier can significantly impact the quality, price, and turnaround time of your project. To ensure the best results when purchasing perforated metal panels, compare several companies using our curated directory of metal panel suppliers. Each supplier profile highlights their experience, product specialties, manufacturing capabilities, and quality certifications.

- Direct Communication: Use the contact form on each supplier’s profile to request detailed information or obtain a customized quote.

- Website Previewer: Quickly browse supplier websites to compare offerings, view galleries, and read technical specs.

- Request for Quote (RFQ): Save time by sending a single RFQ to multiple suppliers and receive competitive proposals tailored to your needs.

- Quality Assurance: Look for suppliers with ISO certification, proven track records, and extensive project portfolios.

- Comprehensive Support: Top suppliers offer design assistance, prototyping, logistics, and installation support.

Ready to get started? Request a quote now or ask our experts about custom solutions, lead times, and pricing.

Frequently Asked Questions About Perforated Metal Panels

What are the most common materials used for perforated metal panels?

The most commonly used materials include aluminum (lightweight and corrosion-resistant), stainless steel (high strength and weather resistance), galvanized steel (cost-effective durability), copper and brass (aesthetic and antimicrobial properties), and specialty alloys for demanding environments.

How do I select the right perforation pattern?

Consider factors such as the required open area, structural strength, airflow, light transmission, and design intent. Consult with your supplier or architect to match pattern specifications to your application.

Can perforated metal panels be customized?

Absolutely. Panels can be tailored in terms of size, shape, pattern, hole diameter, material, finish, and even branding elements like logos or custom graphics.

What is the typical lead time for production and delivery?

Lead times vary based on project complexity, order volume, and customization level. Standard panels may be available from stock, while custom orders typically require 2-6 weeks for production and shipping.

How do perforated metal panels contribute to sustainability?

Many perforated metal panels are recyclable and can be produced from recycled materials. Their energy-saving capabilities (such as sunshading and natural ventilation) contribute to green building certifications and reduced environmental impact.

What are the maintenance requirements?

Maintenance is generally minimal, involving periodic cleaning with mild detergents and inspection of protective coatings. Stainless steel and powder-coated panels offer long-lasting, low-maintenance performance.

Do you offer installation support or technical assistance?

Most top suppliers provide technical support, installation guidance, and even on-site services—ensuring a seamless experience from design to completion.

Still have questions? Contact our team of perforated metal panel experts for personalized assistance.

Case Studies: Perforated Metal Panels in Action

Discover how architects, contractors, and engineers are leveraging perforated metal panels to deliver innovative design, enhanced performance, and long-term value for diverse projects. Below are examples of successful applications:

- Commercial High-Rise Facade: Perforated aluminum panels provide solar shading, reduce HVAC loads, and create a distinctive urban aesthetic.

- Airport Terminal Acoustic Ceiling: Custom perforated steel panels with acoustic insulation dramatically reduce reverberation and improve passenger comfort.

- Industrial Processing Plant: Galvanized perforated metal used for filtration screens, ensuring product purity and system efficiency in a corrosive environment.

- Public Art Installation: Decorative perforated panels in weathered steel form a sculptural gateway and serve as a community landmark.

- Stadium Safety Barriers: Robust, powder-coated panels provide secure perimeter fencing while allowing for airflow and visibility.

Conclusion: Unlock the Potential of Perforated Metal Panels

Whether you’re an architect seeking bold facade solutions, a facility manager improving ventilation or acoustics, or an industrial engineer requiring precision filtration, perforated metal panels offer unmatched versatility, durability, and design freedom. Leverage their benefits to enhance building performance, achieve compliance, and express your unique vision.

Ready to elevate your next project? Request a quote, contact our experts, or browse our FAQs to get started.

Broaching

Broaching CNC Machining

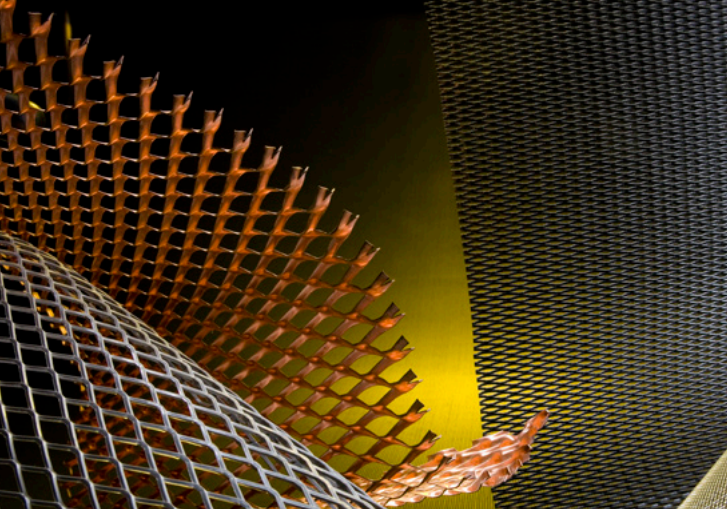

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

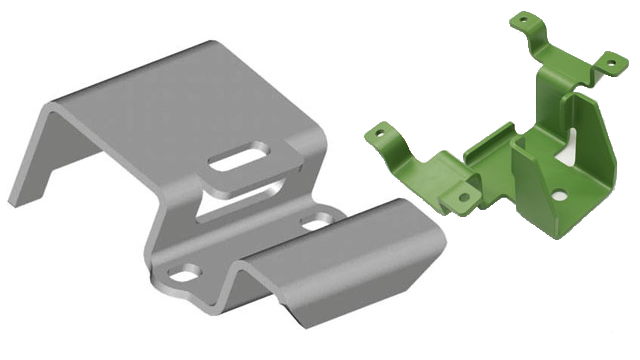

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

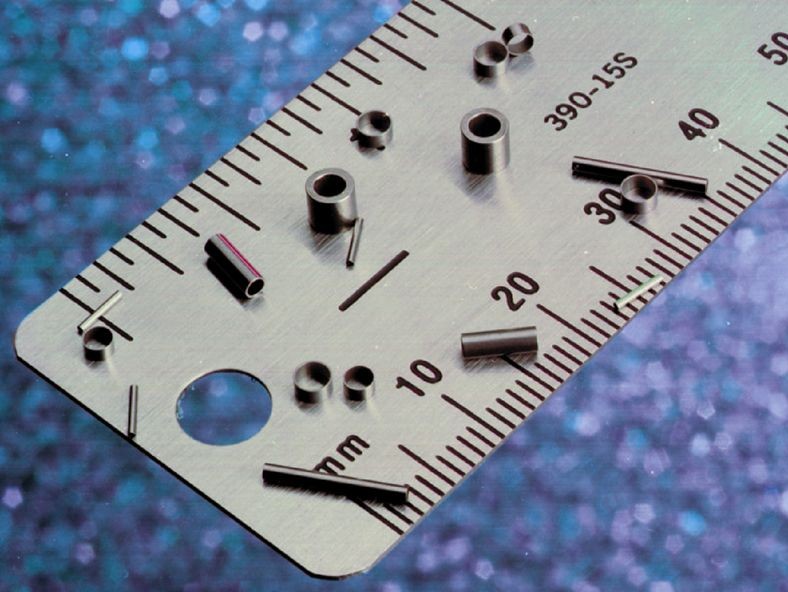

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services