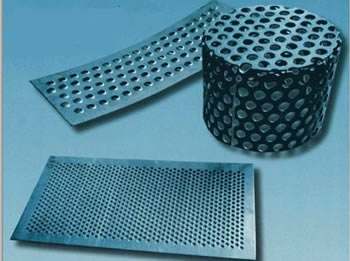

Perforated copper refers to sheets of copper that appear in the form of decorative shapes, with holes punched into their surface. These types of sheets are used for aesthetic or practical means. Perforated copper sheets have a great visual appearance, which results in them being best for interior designs. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Copper Manufacturers

Unfinished copper produces a corrosion-resistant outer surface when exposed to the elements. This outer surface comprises copper carbonate with a greenish tint—commonly known as a patina. Copper metal naturally has an unlimited lifespan and is easy to recycle, making it a sustainable and environmentally friendly material for a wide range of architectural and industrial applications. Its innate antimicrobial properties and natural resistance to corrosion further enhance its appeal in both commercial and residential settings. Are you curious about the environmental benefits or long-term durability of copper for your next project?

How Perforated Copper is Made

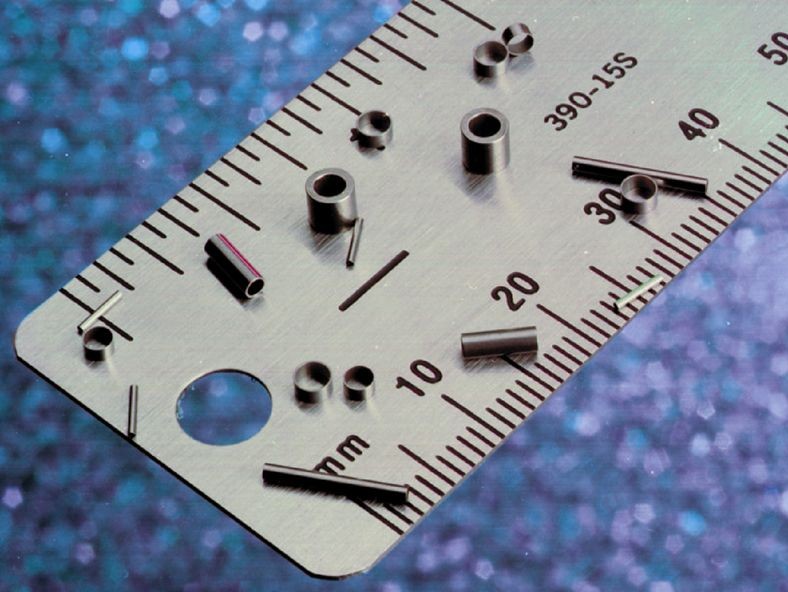

As with most perforated metals, copper products are produced using a stamping press, a key process in metal fabrication. The press punches usually need the help of a CNC (Computer Numerical Control) machine because many copper perforations have decorative, complex, and intricate patterns. This technology allows for precise and repeatable designs, whether you require traditional round holes or custom architectural patterns.

Punch presses operated by CNC produce higher precision and accuracy; however, they are less efficient for mass production compared to traditional methods. The perforation process starts with large rolls of copper sheet metal inserted into the punching machines. This sheet metal can vary in thickness and gauge, depending on the intended application—from lightweight decorative screens to heavy-duty industrial filters.

Next, the machinery moves the copper sheet around in both axes underneath a stationary punch. The machinery then punctures designs into the copper sheet using high volumes of weight and force. Punching presses can stamp through the metal at a rate ranging from 50 to 400 strokes per minute. This rate depends on the copper sheets' thickness and the pattern's difficulty. Would you like more details about custom perforation techniques or which machine best suits your project? Contact our perforation experts for advice.

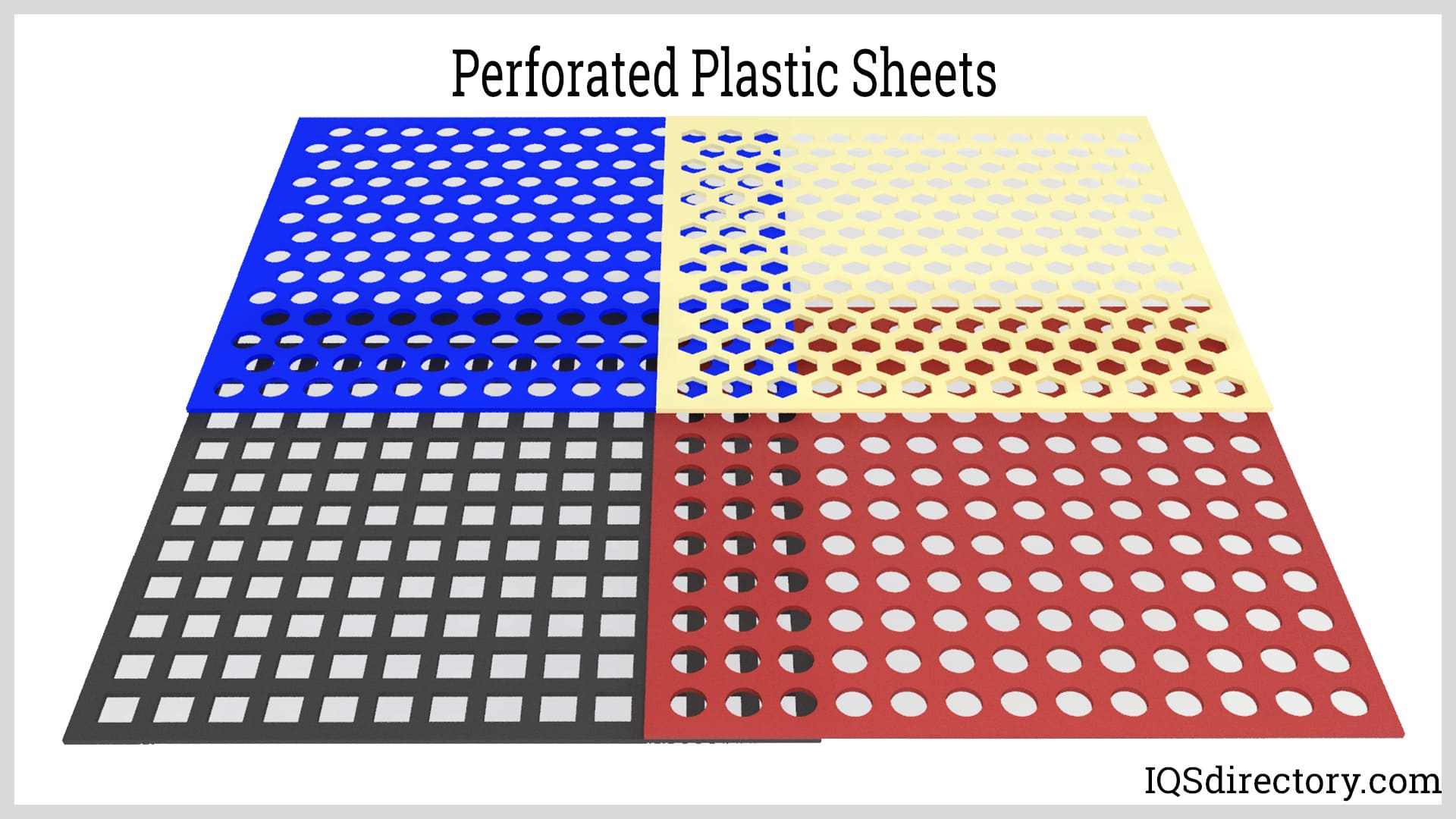

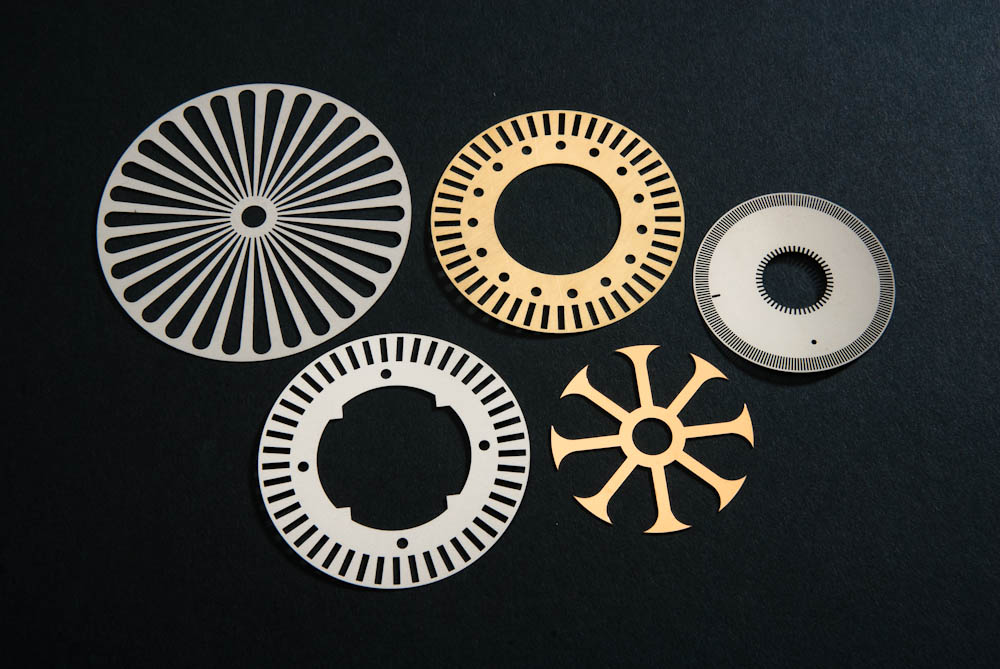

Manufacturers can produce a wide range of designs because copper is a malleable metal. The patterns can range from small and widely spaced to screen-like with high transparency and gauges. Perforated copper products can be polished or finished with various coatings and are often used for decorative, architectural, and functional purposes. The versatility of copper enables it to be used in applications such as acoustical panels, light diffusers, and ventilation grilles. If you are researching innovative uses for perforated copper, consider how custom patterns can add both functionality and aesthetic value to your designs.

Types of Perforated Metal Machinery

Various types of machinery can be used for the perforation process, depending on the design or pattern produced. These machine types are tailored to accommodate both simple and complex copper perforation requirements, from basic industrial screens to elaborate decorative panels. Understanding the capabilities of each perforating machine can help you select the most efficient and cost-effective production method for your project.

Wide Punch Press

A wide punch press machine is designed for high-speed, high-volume production runs. Metals are inserted into it in the form of coiled rolls or sheets, making it ideal for continuous processing. The ram rapidly strikes the metal as the material passes through the wide punch press, producing a complete row of holes in a single movement. This type of machinery can create perforated copper sheets at a faster pace and in larger quantities, making it suitable for commercial and industrial projects where uniformity and efficiency are crucial.

- Best suited for repetitive patterns and large production batches.

- Minimizes material waste and ensures consistent quality.

- Often used for ventilation panels, safety guards, and machine enclosures.

XY Axis Punch Machine

An XY axis punch machine contains a single die or a collection of dies connected to the ram. The metal material to be perforated remains stationary while the ram moves across it, enabling the formation of various punches. This configuration makes the XY axis punch machine especially useful for custom projects that require non-repetitive, intricate designs or variable hole sizes and patterns.

Although XY axis punch machinery generally takes more time to produce perforated metals, it offers a wide range of shapes and design flexibility within a single workpiece. Incorporating CNC technology further enhances alignment and accuracy, making it ideal for architectural panels, signage, and bespoke design features. Are you evaluating different punch machine options for your custom project?

- Perfect for prototypes and small to medium production runs.

- Allows for highly customized patterns and precision placement.

- Supports complex geometries and artistic applications.

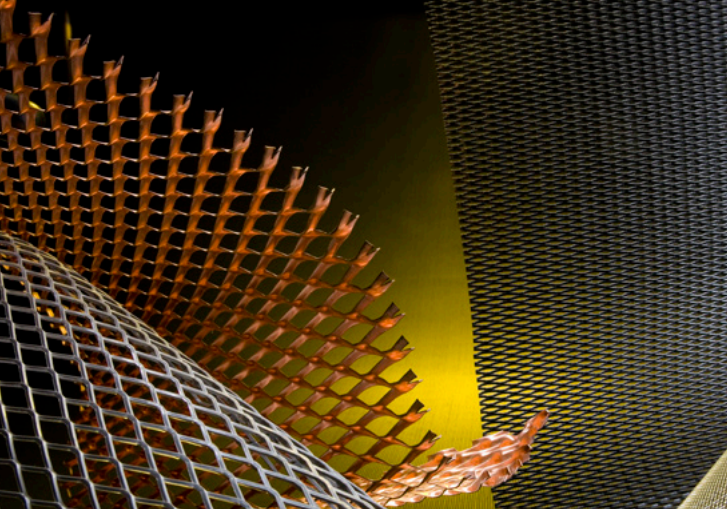

Rotary Pinned Roller Perforating Machine

The rotary pinned roller perforating machine features a large cylinder assembled with pointed needles, precisely spaced around the circumference. As the sheet metal is fed under the rotating roller, the needles puncture the metal, creating extensive rows of holes in a single, continuous operation. This process is remarkably fast and efficient, making rotary pinned roller machines the preferred choice for applications requiring high throughput and uniformity.

- Ideal for producing fine mesh, filters, and screens.

- Enables continuous perforation of long copper sheets or coils.

- Common in industries such as HVAC, filtration, and food processing.

Applications and Uses of Perforated Copper

Perforated copper is an exceptionally versatile material used across a spectrum of industries and architectural applications. Its unique combination of malleability, conductivity, and corrosion resistance makes it suitable for both functional and decorative uses. If you are exploring how perforated copper can enhance your project, consider the following common and innovative applications:

Architectural and Interior Design

- Exterior Building Design: Perforated copper panels are popular for building facades, sun shades, and cladding due to their ability to withstand extreme temperatures and resist rusting. Over time, copper forms a natural patina, offering a distinctive, visually appealing green finish that adds character to any structure.

- Interior Design: Inside buildings, perforated copper is used for room dividers, fireplace screens, kitchen cabinet inserts, and feature walls. The metal's warmth and color provide a luxurious, timeless aesthetic while also offering practical benefits such as airflow and light diffusion.

- Acoustic Solutions: Perforated copper panels can be integrated into ceilings and wall systems to improve acoustics while maintaining a sleek, modern look.

Industrial and Functional Applications

- HVAC and Ventilation: Copper's thermal conductivity and resistance to microbial growth make perforated copper ideal for heating, ventilation, and air conditioning components, including grilles and filters.

- Radiator Covers: Perforated copper is commonly used to cover radiators, efficiently concealing the unit while allowing heat to circulate effectively.

- Electrical and Electronics: Due to its excellent electrical conductivity, copper perforated sheet is used for EMI/RFI shielding in sensitive electronic equipment and for grounding plates in electrical enclosures.

- Filtration and Screening: In industries such as food processing, chemical manufacturing, and water treatment, perforated copper is valued for its durability and resistance to corrosion, making it ideal for strainers, sieves, and screens.

- Lighting and Decorative Fixtures: Perforated copper can be fashioned into decorative lamp shades, light diffusers, and backlit wall panels, offering both functionality and artistic appeal.

- Security and Safety: Used in safety guards, machine enclosures, and protective barriers, copper’s sturdy nature ensures long-lasting security solutions.

Benefits of Perforated Copper

Choosing perforated copper for your project offers a range of advantages that extend beyond its striking appearance. Here are some key benefits that make copper a preferred choice for designers, engineers, and builders:

- Exceptional Durability: Copper resists corrosion and stands up to harsh environmental conditions, even in coastal or industrial settings.

- Natural Antimicrobial Properties: Copper surfaces inhibit the growth of bacteria, viruses, and fungi, making it ideal for public spaces, healthcare facilities, and kitchens.

- Recyclability and Sustainability: Copper is 100% recyclable without any loss in quality, contributing to green building standards and LEED certification.

- Unique Aesthetic Appeal: The metal's evolving patina and warm tones offer a customizable look that can be tailored to modern, traditional, or contemporary designs.

- Superior Conductivity: Copper’s high electrical and thermal conductivity make it indispensable in electrical and HVAC applications.

- Design Flexibility: The malleability of copper allows for intricate perforation patterns and custom fabrication to meet specific project needs.

- Low Maintenance: Copper’s natural resistance to tarnishing means it requires minimal upkeep, retaining its beauty and functionality for decades.

Buyer’s Guide: Choosing the Right Perforated Copper Supplier

Selecting the right supplier is critical to ensuring the success of your perforated copper project. Whether you need architectural panels, industrial filters, or custom perforated copper sheets, partnering with an experienced and reputable supplier can make all the difference. Here are some essential decision factors and tips to guide your selection process:

Key Considerations When Evaluating Suppliers

- Experience and Expertise: Look for suppliers with a proven track record in manufacturing high-quality perforated copper products for your specific industry or use case.

- Customization Capabilities: Ensure the supplier can accommodate custom patterns, gauges, sheet sizes, and finishing options to meet your project’s unique requirements.

- Quality Assurance: Confirm that the supplier adheres to strict quality control standards and can provide product certifications or compliance documentation as needed.

- Lead Times and Delivery: Assess the supplier’s production capacity and delivery timelines, especially if your project has tight deadlines or requires large quantities.

- Customer Support: Choose a supplier that offers responsive customer service, technical support, and guidance throughout the project lifecycle.

- Pricing and Value: Request detailed quotes and compare pricing structures, keeping in mind that the cheapest option may not always deliver the best quality or performance.

How to Compare Perforated Copper Suppliers

To ensure you have the most positive outcome when purchasing perforated copper from a perforated copper supplier, it is important to compare several companies using our comprehensive directory of perforated copper suppliers. Each perforated copper supplier has a dedicated business profile page highlighting their areas of experience, production capabilities, and project portfolio, along with a contact form to directly communicate for more information or request a quote.

Review each perforated copper business using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ (Request for Quote) form to contact multiple perforated copper companies with the same form, enabling you to efficiently gather and compare proposals.

- Search for suppliers by location, specialization, or application focus.

- Read customer testimonials and case studies to gauge supplier reliability.

- Request product samples to evaluate quality firsthand.

- Ask about after-sales support, installation guidance, and warranty options.

Have questions about sourcing, lead times, or bulk order discounts? Reach out to our team for personalized assistance.

Frequently Asked Questions About Perforated Copper

What sizes and thicknesses are available for perforated copper sheets?

Perforated copper sheets are available in a variety of standard and custom sizes, with thicknesses ranging from lightweight 0.5mm up to heavy-duty 6mm or more. Popular sheet dimensions include 24” x 36”, 36” x 48”, and custom cuts to suit unique project needs. The gauge, hole size, and open area percentage can be tailored for specific applications, from fine mesh to large decorative patterns.

Can perforated copper be finished or coated?

Yes, perforated copper can be finished with various coatings, including clear lacquers, powder coatings, or patina accelerators. These finishes can enhance appearance, increase durability, or achieve a specific aesthetic effect. Polished, brushed, or antique finishes are also available to complement different design styles.

Is perforated copper suitable for outdoor applications?

Absolutely. Copper’s inherent corrosion resistance and durability make it highly suitable for exterior use. Over time, copper will naturally develop a protective patina, shielding the underlying metal and minimizing maintenance requirements. This makes perforated copper ideal for facades, roofing, sunshades, and outdoor art installations.

How do I maintain and clean perforated copper panels?

Perforated copper is low-maintenance, often requiring only occasional dusting or gentle washing with mild soap and water. Avoid harsh chemicals or abrasive tools, as they may damage the patina or finish. For polished copper, periodic buffing with a copper cleaner can restore shine, while patinated finishes should be left to age naturally.

Where can I find design inspiration or technical resources for perforated copper projects?

Visit our project gallery for examples of completed projects, or browse our technical resources for detailed specifications, installation tips, and design guides. Looking to start your own project? Request a quote today.

Get Started with Your Perforated Copper Project

Whether you are an architect, designer, fabricator, or engineer, perforated copper offers unmatched flexibility, beauty, and performance for your next build. From custom decorative panels to robust industrial components, our network of expert suppliers is ready to help you bring your vision to life. Searching for guidance on selecting the right perforated copper solution? Connect with our specialists for a free consultation and material sample.

Ready to get started? Request your custom quote now.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

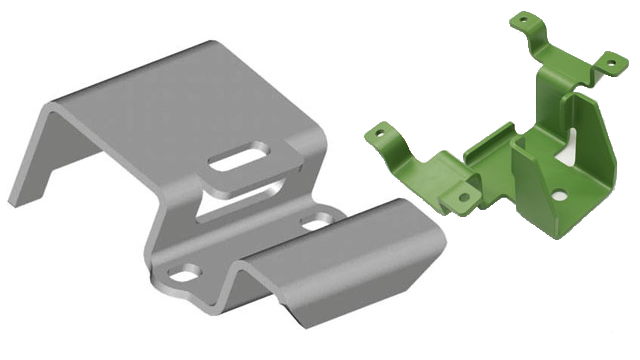

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services