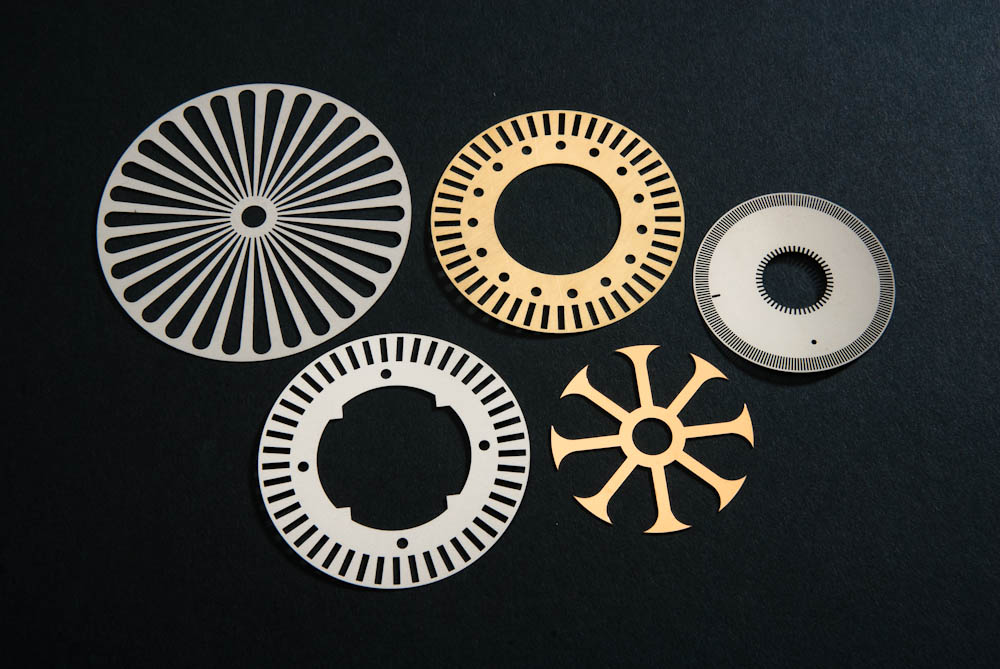

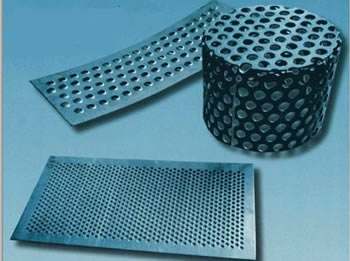

Perforated tubes’ standard perforated patterns are straight, staggered or oblong staggered, but many manufacturers are able to produce tubes with custom perforated patterns. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Our commitment to excellence is reflected in the superior quality of our perforated metal products. We understand the diverse needs of our customers, and our extensive range of perforation patterns and materials ensures that we can meet and exceed expectations across various industries.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Tube Manufacturers

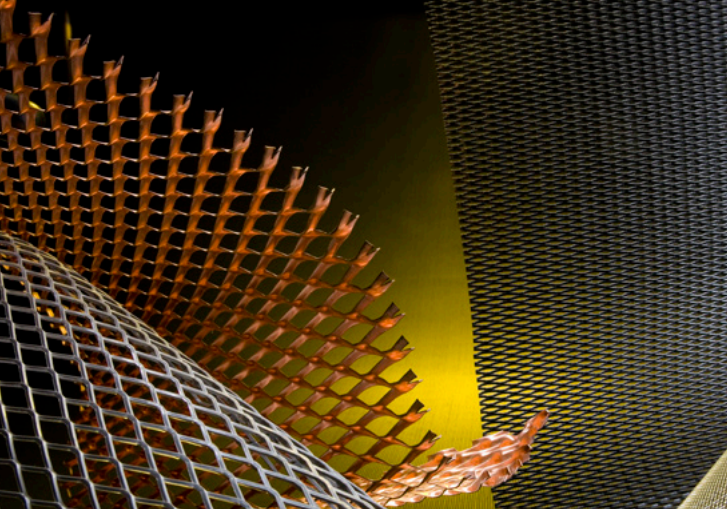

Their open hole area size is determined by the minimum size of the particulates being trapped within the tube. Though the perforations are usually round, some tubes are made with square or slot-shaped holes.

Perforated metal tubes, unlike many other perforated metal varieties, are infrequently used for decorative purposes. They are sometimes used in pieces of industrial art, but they are generally restricted to use as industrial utilities.

The most visible applications of perforated metal tubes are exhaust systems. Wide, corrosion-resistant perforated exhaust pipes are standard on most large trucks and in some sport cars and high-performance utility vehicles. Perforated metal tubes are also used in Bunsen burners and other gas-fired heating apparatus.

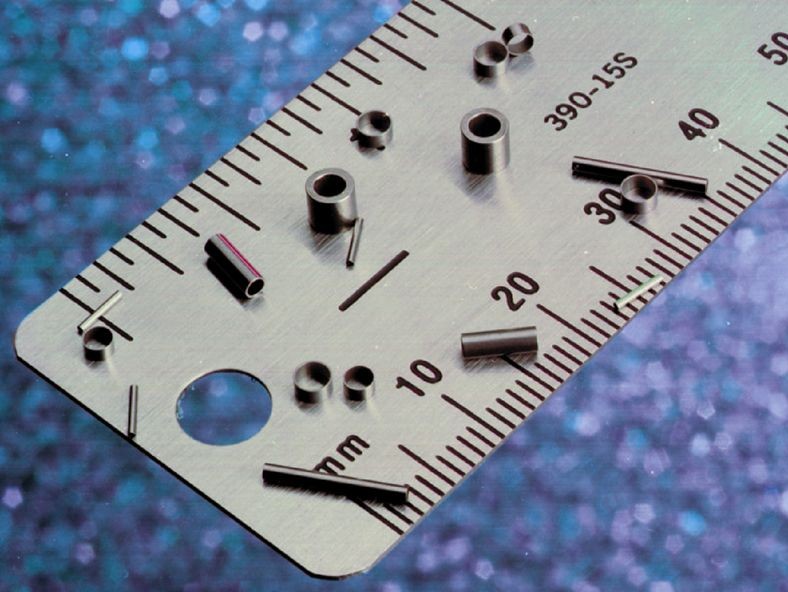

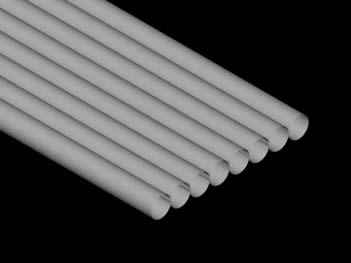

During the perforated metal tube manufacturing process, every tube is inspected for hole diameter accuracy. The perforated pattern in tubes is made by machines called punch presses, which cut holes in rolled sheet metal.

For many years, punch presses were operated manually by technicians. Today, punch presses are often controlled by computer software, which is called Computer Numerical Control software.

Using CNC punch presses is less time-intensive than manual punch pressing and requires a lower investment in labor costs. Whether a punch press is manual or automatic, it involves a ram or stamp that exerts pressure on a metal, which makes hole-shaped cutouts in the sheet.

Perforated tubes are most often made of stainless steel or carbon steel, although aluminum is sometimes used. After perforation, the sheet metal is cut to size and welded or fastened into the tube form.

Perforated tubing manufacturers often provide end forming operations, which include sizing, reducing, flaring and bulging. In high strength applications, the metal may be strengthened by tempering, quenching or a galvanizing processes.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services