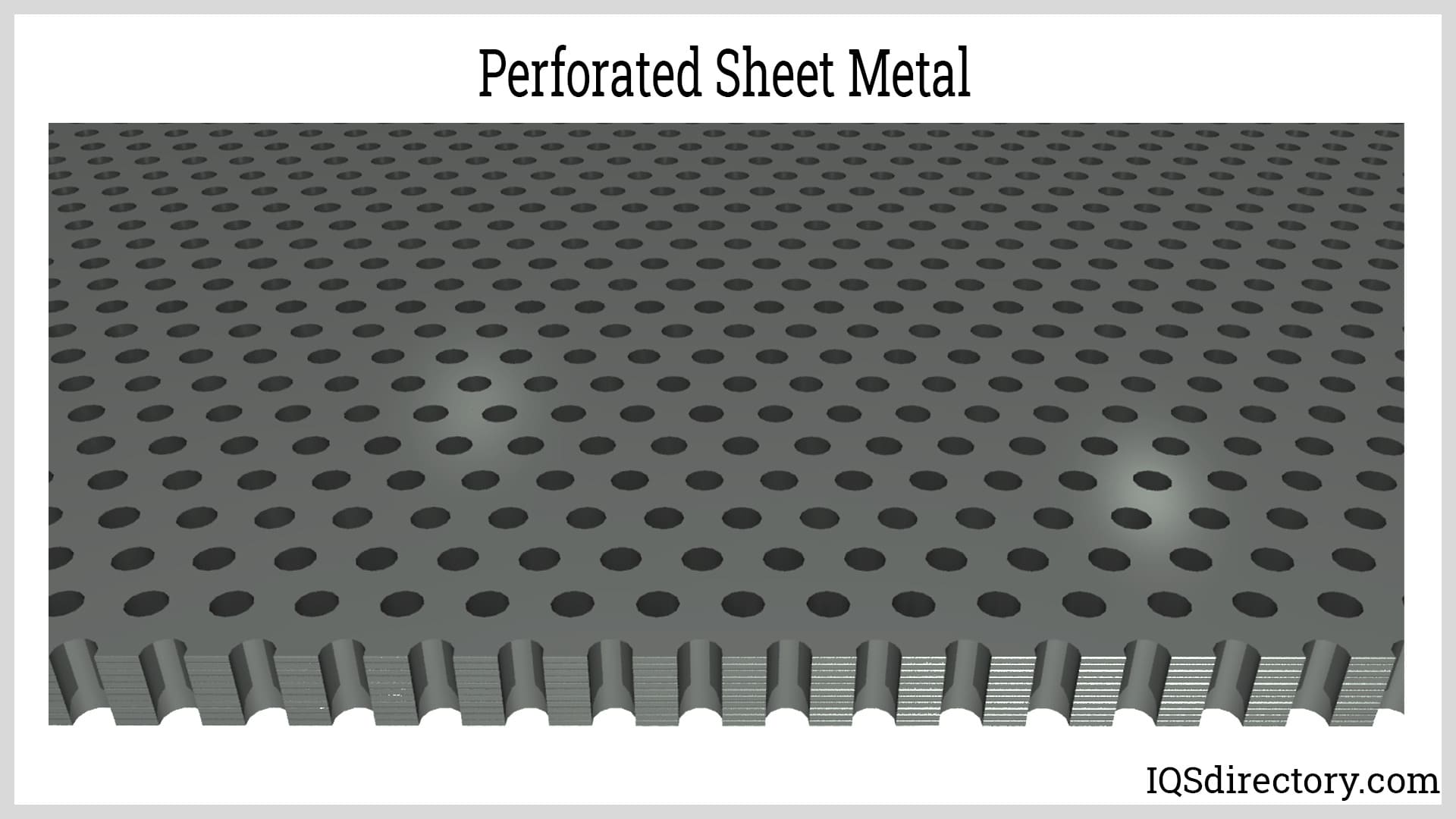

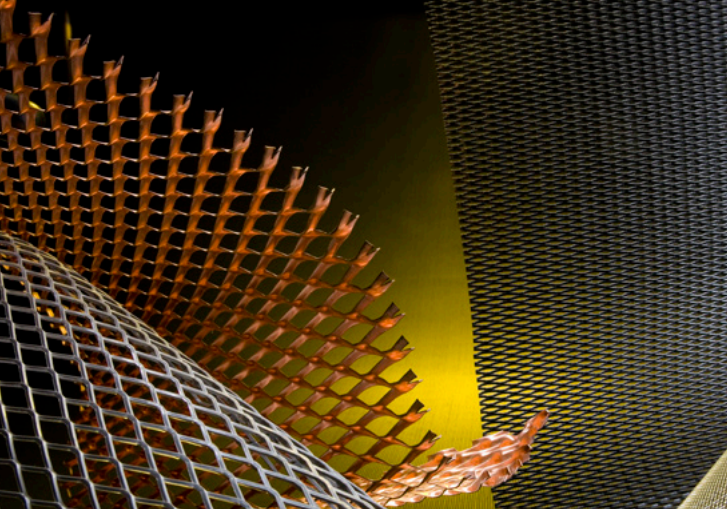

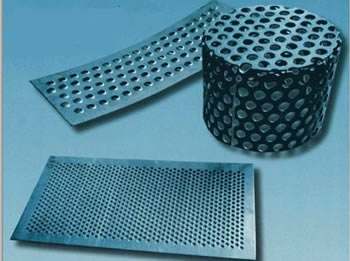

Metal sheets patterned or serially stamped with holes, or other shapes are called perforated sheets. “Sheet” is frequently used to describe relatively thin metal planes. Compared to expanded metal and wire mesh, perforated metal sheets are lighter and have a higher load-bearing capability. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Our commitment to excellence is reflected in the superior quality of our perforated metal products. We understand the diverse needs of our customers, and our extensive range of perforation patterns and materials ensures that we can meet and exceed expectations across various industries.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Sheet Manufacturers

Functions of Perforated Metal Sheets

Perforated metal sheets are produced using metal punching techniques for excellent weight reduction and great filterability. In addition, perforation provides numerous benefits for a variety of applications, including noise reduction, heat dissipation, and other benefits such as:

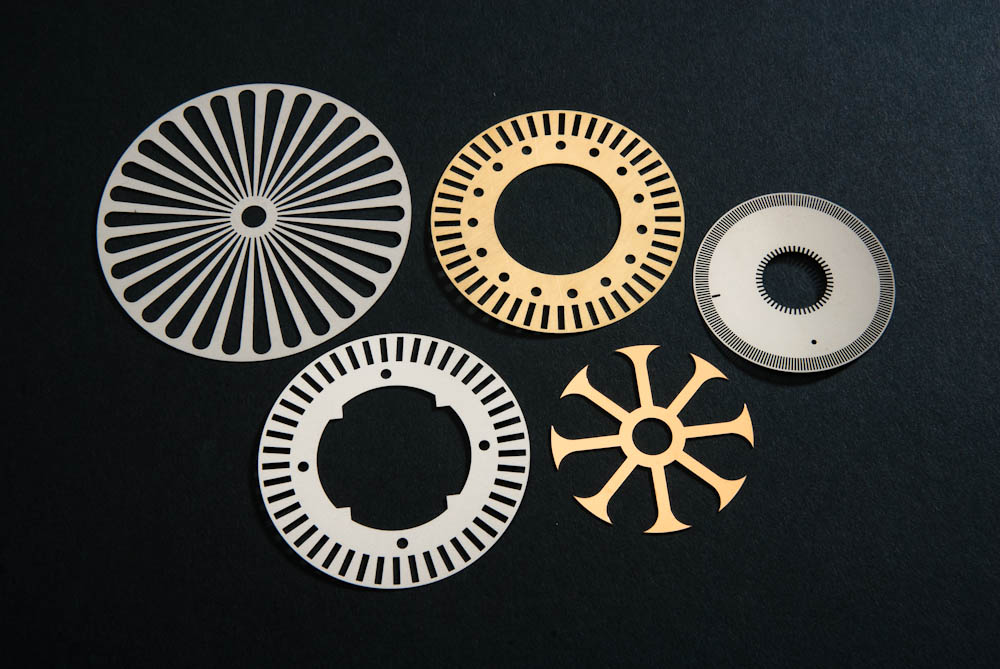

Versatility: The shapes and sizes of the perforated metal sheets might vary. They may have patterns of circles, square holes, and geometric shapes. Every design is distinct and fulfills a different function. For mesh or window nets, fine squares or circles are ideal. Complex hexagonal designs like vents and footboards can be used for structural functions. The layout and shapes can be changed in any way. Before choosing a pattern, one should be certain of the sheet's purpose.

Acoustic Performance: The high open area of the perforated metal sheet allows sound to pass through freely while also shielding the speaker from harm. Perforated metals are often used as speaker grilles. Furthermore, they can reduce noise to give you a comfortable environment.

Sunlight and Radiation Containment: Recently, more architects have adopted perforated steel sheets as sunshades to decrease solar irradiation without any block of view.

Heat Dissipation: Because perforated sheet metal has a heat-dissipating characteristic, the need for air conditioning can be greatly decreased. Research shows that using a perforated sheet in front of a building facade can result in 45% energy savings. As a result, perforated metal sheets are often used in architectural applications like cladding and building facades.

Perfect Filterability: Perforated stainless steel and aluminum sheets are frequently used as sieves for bee hives, grain dryers, wine presses, fish farming, hammer mill screens, window machine screens, etc., because of their excellent filtration ability.

Anti-Skid: Aluminium sheets with embossed perforations are used as anti-skid plating in workplaces, industrial facilities, stair treads, transportation hubs, etc. They decrease the likelihood of slipping on wet or icy pavement.

Protective Function: Perforated sheets are strong enough to shield machinery and act as balcony guardrails.

Features & Benefits of Perforated Sheet

Perforated sheets come in various patterns, gauges, and materials. They can have circles, squares, triangles, hexagons, diamonds, or custom shapes punched into them. They often have a high strength-to-weight ratio. Perforated metal sheets are affordable, flexible, functional, and aesthetic. They can filter fluids, air, light, sound, and gases.

Perforated Sheet Materials

Aluminum, copper, brass, zinc, stainless steel, and copper are all used for perforated sheets. Perforated sheets are popular for many uses, including enclosures, partitions, sign panels, guards, screens, and more. Regular flat sheets are punched in a predetermined pattern for aesthetic or functional purposes to produce perforated sheets. In applications like ventilation or filtering where the passage of water or air is essential, perforated metal sheets are frequently employed. However, these sheets are often extremely light and thin because of the punched pattern. A few common applications are partitions, enclosures, guards, sign panels, and screens.

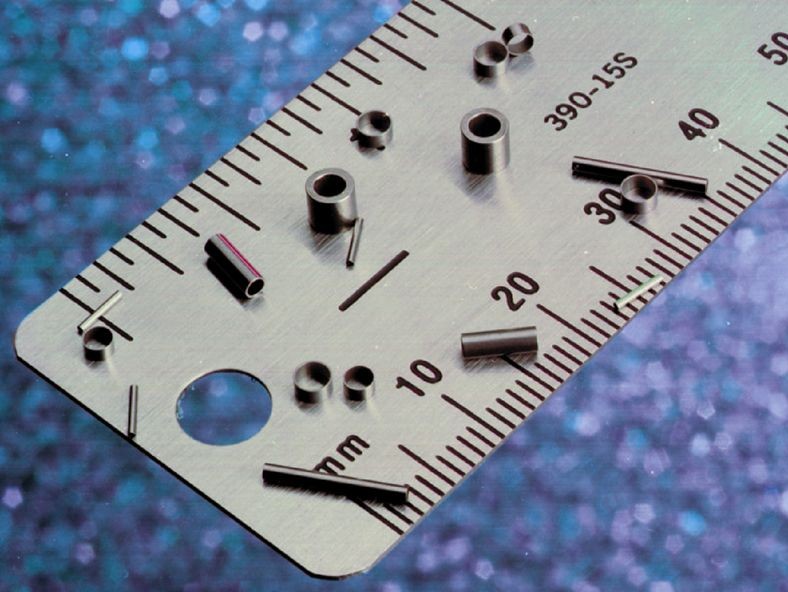

Equipment Used in Manufacturing Perforated Sheets

All-cross punch presses and sectional two-axis punch presses perforate sheet metal. All-cross punch presses are designed for straightforward, repeatable designs that cover the entire sheet. The thin metal sheet is punctured by these metal shaping machines' rams, which are shaped in the required pattern. More intricate and unique designs are punched using sectional two-axis punching machines. Metal sheets are moved below a stationary punching ram by sectional two-axis presses to create non-repetitive holes. They are frequently computer-controlled and capable of producing highly detailed designs.

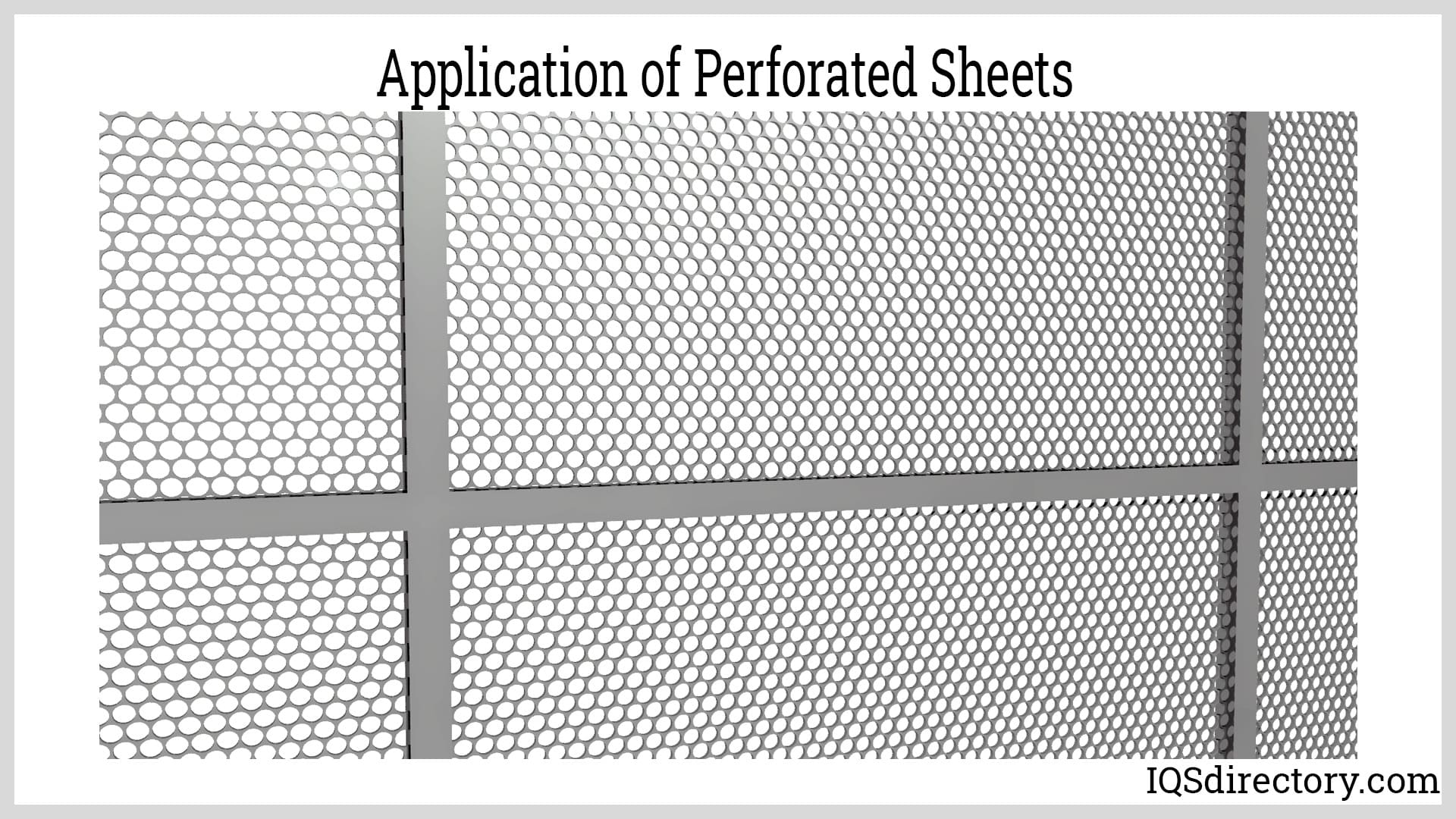

Applications of Perforated Sheets

One can find examples of perforated sheets in the automotive, lighting, architecture, construction, agriculture, mining, interior design, and defense industries. Additionally, acoustic dampening systems in recording studios and huge, noisy transportation hubs like train stations and subway stops can be made with perforated sheet metal as a component. Perforated sheet metal can create a wide range of additional products, including baskets, kitchenware, and garbage cans. There are few restrictions on the material's application options because of its adaptability.

Choosing the Proper Perforated Sheet Supplier

To ensure you have the most productive outcome when purchasing perforated sheets from a perforated sheet supplier, it is important to compare several companies using our directory of perforated sheet suppliers. Each perforated sheet supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each perforated sheet business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple perforated sheet businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

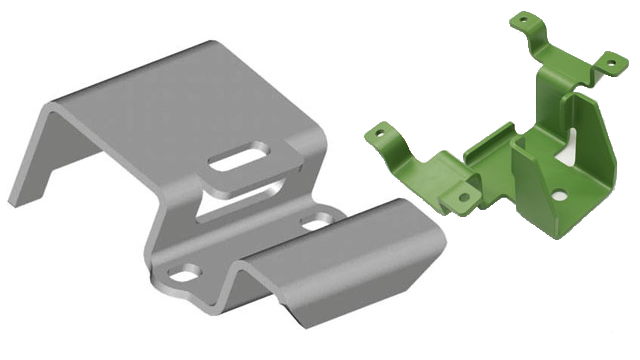

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services