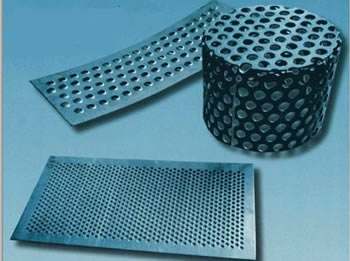

The term perforated sheet metal refers to sheet metal that has been manually or mechanically stamped, punched, or pierced using CNC technology or, in some cases, laser cutting to produce various hole sizes, shapes, and patterns. The perforation procedure allows for the unlimited shaping and machining of metals. Read More…

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the...

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

Our commitment to excellence is reflected in the superior quality of our perforated metal products. We understand the diverse needs of our customers, and our extensive range of perforation patterns and materials ensures that we can meet and exceed expectations across various industries.

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques

More Perforated Sheet Metal Manufacturers

The type of metal to perforate depends on how the perforated sheet will be used. Metals that are sturdy, long-lasting, and strong are put through this procedure for use in structural applications and industrial processes; fore example, aluminum and copper are two lightweight metals that can be easily stamped and punched. Steel and titanium are examples of harder metals that require a more aggressive technique but can still be penetrated.

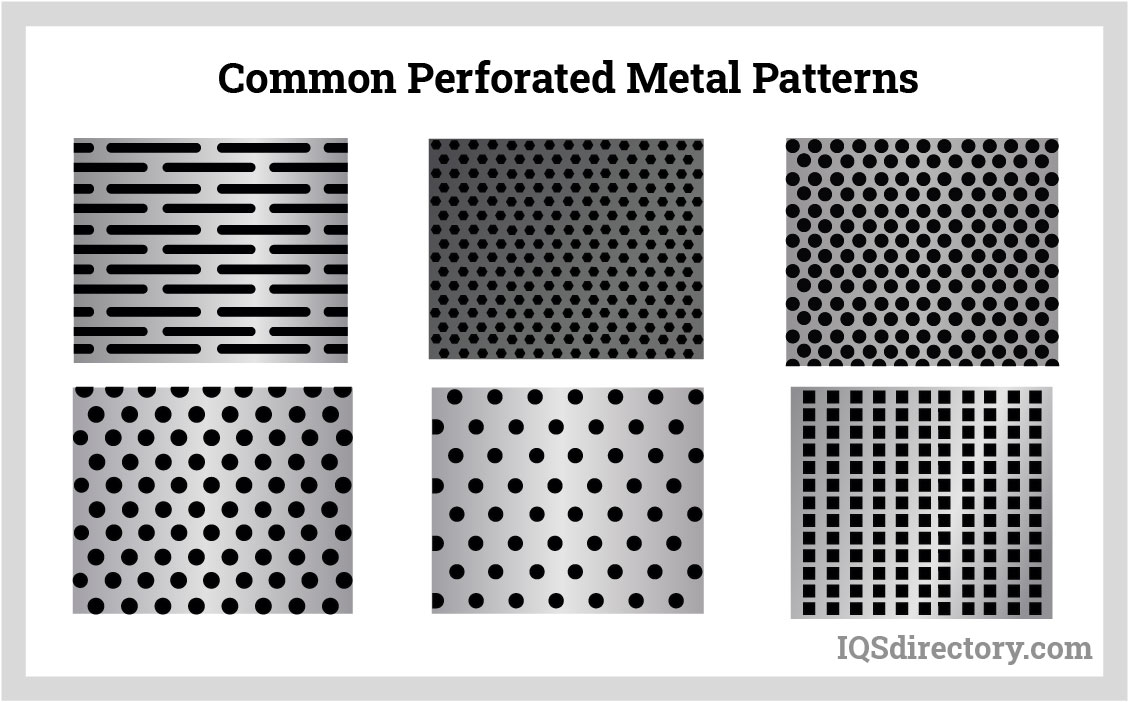

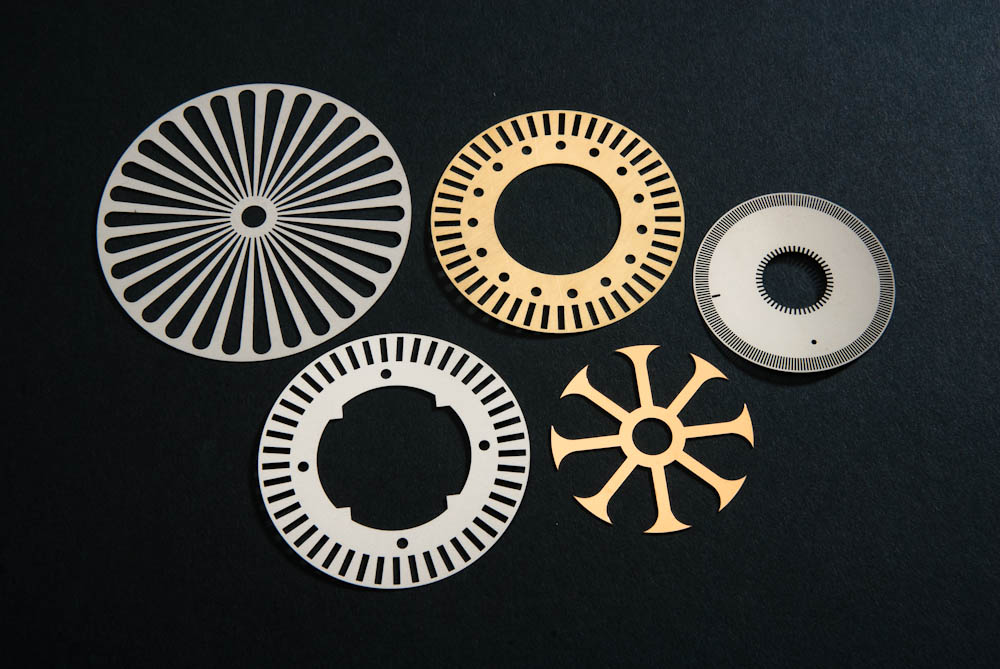

Types of Perforated Sheet Metal

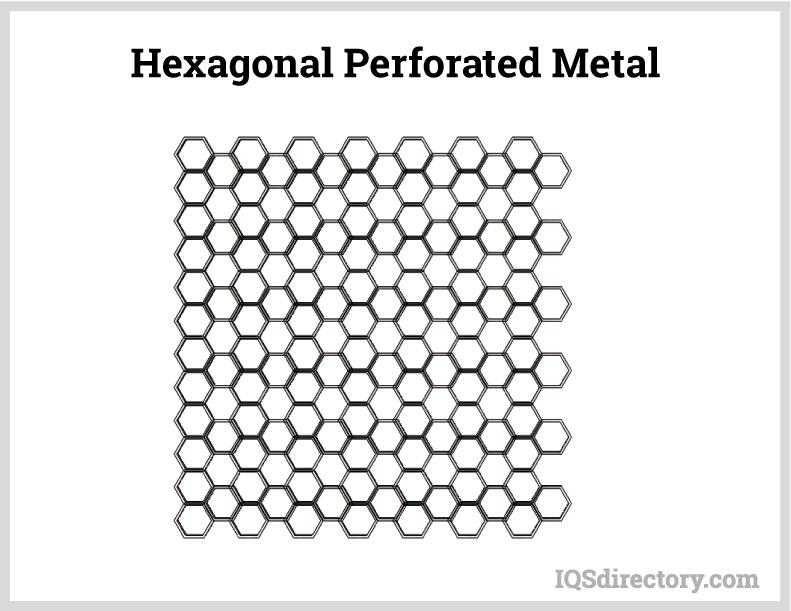

Hexagonal Perforations

The maximum amount of open space is found in hexagonal (honeycomb) perforated metal patterns, which are used in architectural designs that need constant ventilation. The staggered arrangement of the holes for the hexagonal pattern places the middle of one hole on the edge of the following hole. Because it offers numerous advantages in numerous areas, a hexagonal perforated metal sheet is superior to traditional metal sheets. It is strong, durable, and can endure high temperatures. Additionally, due to its low density, it won't significantly add weight to the project or building. A hexagonal perforated sheet is lighter and easier to recycle than other shapes. Metal sheets with hexagonal perforations can be used for fencing.

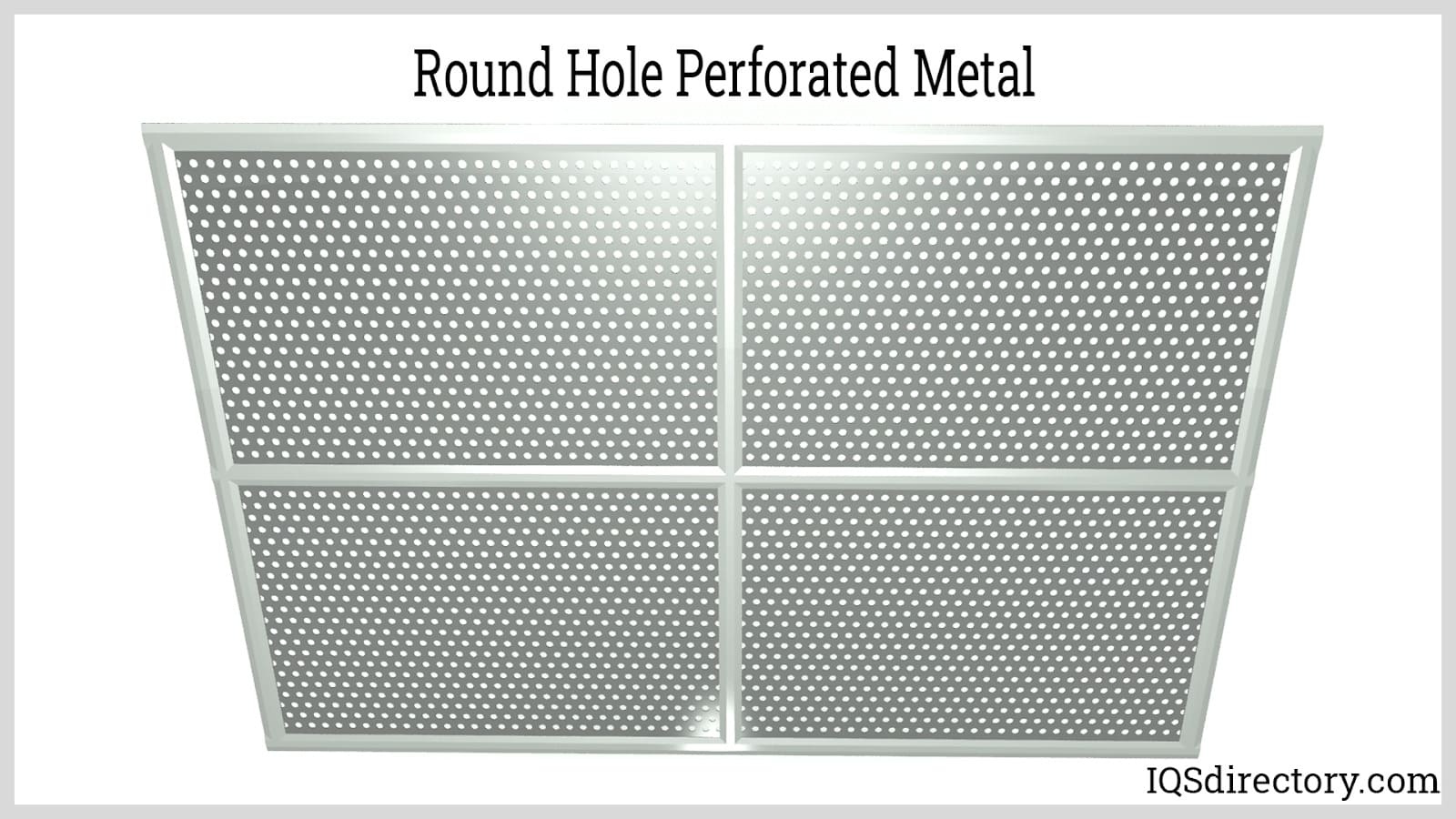

Round-Hole Perforations

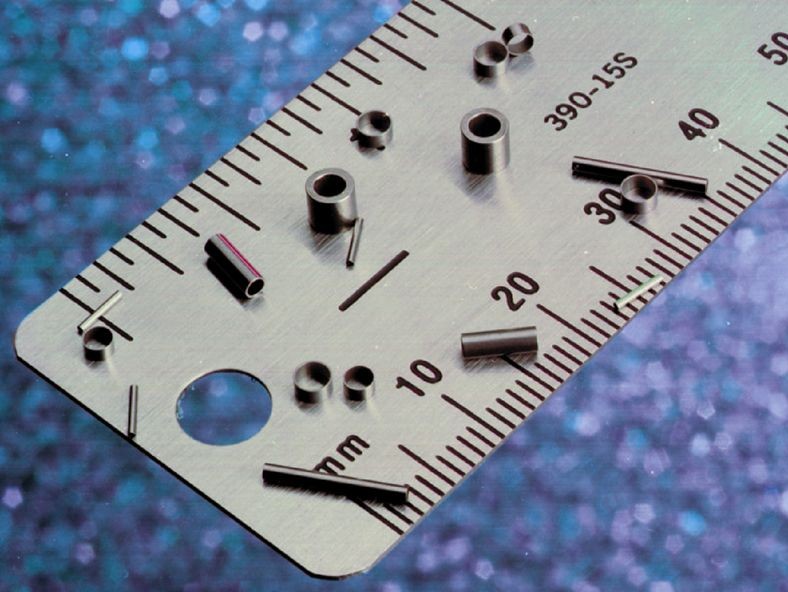

The optimum mix of ease of manufacture, minimal maintenance, and affordability is provided by round-hole perforated sheet metal. In the long run, round-hole perforated metal is the most economical solution because it lasts longer than the other types. Round holes can be punched in either straight or staggered lines.

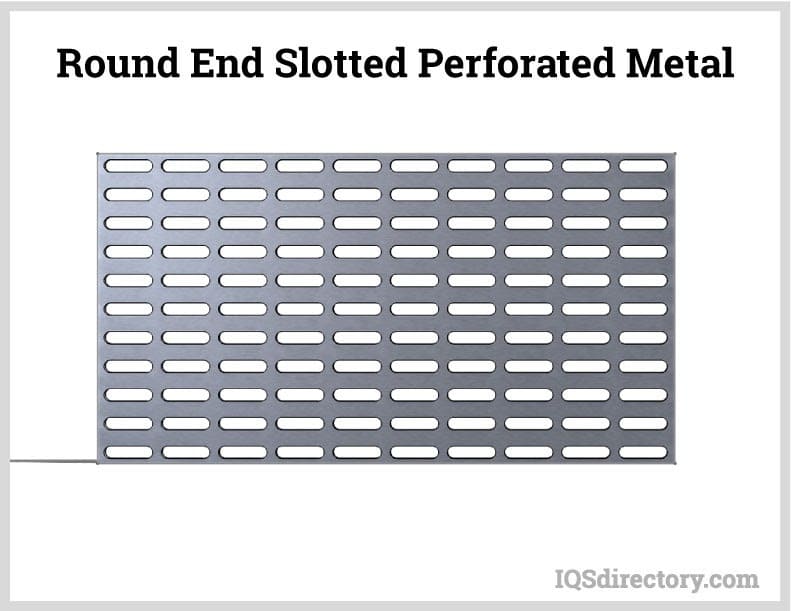

Slotted Perforations

Slotted perforated metal features elongated holes with round or square ends that can be arranged in a pattern that is either staggered or straight. A slotted die is used to punch the holes for the slotted pattern. Slotted perforated metals are exceptionally strong for their weight and permit the passage of liquids, light, and sound. The diameter and length of the die's holes might vary. Slotted perforated metal is uniquely constructed so a lot of material can pass through without negatively impacting the metal sheet's overall strength and performance.

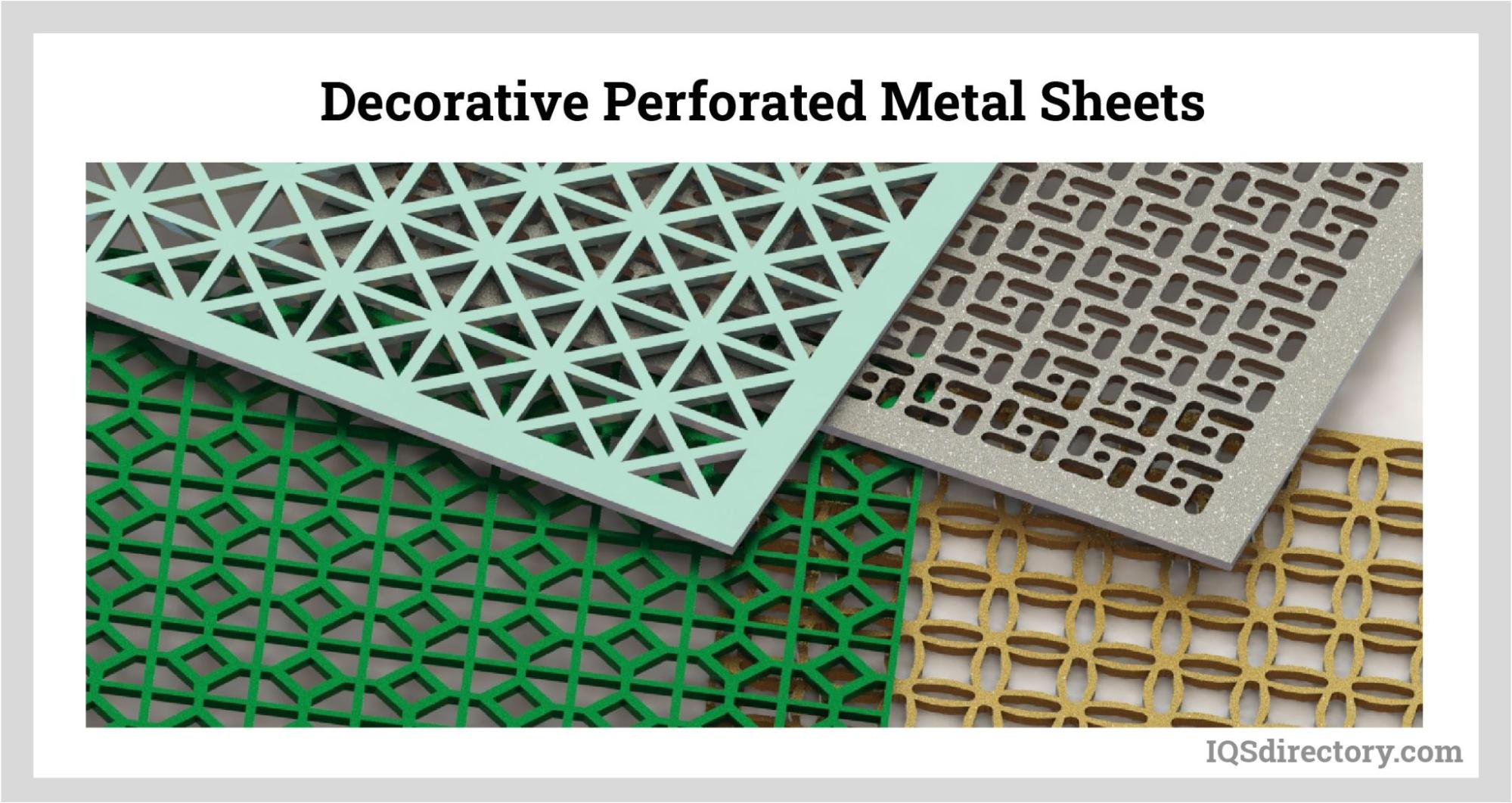

Decorative Perforations

Decorative perforated metals are architectural accents that add aesthetic appeal. They are specifically created to match the requirements of a building's layout and are available in a wide range of shapes and patterns. The capacity to improve the appearance of the perforated metal and adapt it to any application is made possible by these decorative patterns that alter the shape of the pattern die.

Applications of Perforated Sheet Metal

- Electronics: Due to their breathability, perforated sheet metals can be utilized in electrical and electronic components to prevent overheating of components.

- HVAC: Metals with perforations are excellent for evenly dispersing airflow and attenuating HVAC system noise. Metal perforated diffusers promote airflow that prevents stale air, cold flooring, and heat bursts.

- Risers And Treads for Stairs: Perforated metal's strength and durability make it a fantastic option for stair treads and risers because of its improved slide resistance and high load-bearing capability for structural integrity.

- Architecture: Perforated metals have been employed in construction for some time. Today's perforated metals for architectural projects may be produced quickly and in a wide range of shapes, styles, and configurations thanks to several technological and machining developments.

- Interior Layouts: Perforated sheet is superior to other upgrading materials that one can use in the interior decoration of their homes. Smaller design elements can also be made of perforated metal, which gives the interior's wood and glass a more industrial feel.

- Fencing and Screening: The initial option for fencing private mixtures is a perforated sheet. Due to their strength, durability, and appealing appearance, perforated sheets are well-regarded in the industry.

Benefits of Perforated Metals

- Metal Perforation Strength: The Equivalent Solid Material Concept compares perforated metals to solid metals to determine how strong they are. Engineers conduct a solid comparable materials test to assist designers in deciding which perforated materials to utilize.

- Sound Cancellation: Metals with holes serve a variety of purposes, including lighting and aesthetics. As a form of sound absorption, they provide one of their most beneficial purposes. Unwanted noise is diminished through the perforated panels. Their porous, textured surface, which can be used both inside and outside, disperses sound waves.

- Ventilation: Perforated metal is used in construction to increase shade and improve airflow when ventilation needs to be improved. The energy expenses for heating, ventilation and air conditioning are reduced as a result of this approach to safeguarding buildings.

- Long-Term Impact: Perforated metals' versatility gives designers and builders a variety of alternatives to improve long-lasting building construction. Since perforated metals may be custom-crafted to match any situation, they can be produced in a way that gives any structure a long-lasting, irreversible impression. Compared to other materials used for the same purpose, perforated panels are stronger and more weather-resistant when compared to other materials used for the same purpose, perforated panels are stronger and more weather-resistant when they are manufactured and produced.

Choosing the Proper Perforated Sheet Metal Manufacturer

To ensure you have the most constructive outcome when purchasing perforated sheet metal from a perforated sheet metal manufacturer, it is important to compare several companies using our directory of perforated sheet metal manufacturers. Each perforated sheet metal manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each perforated sheet metal business using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple perforated sheet metal companies with the same form.

Broaching

Broaching CNC Machining

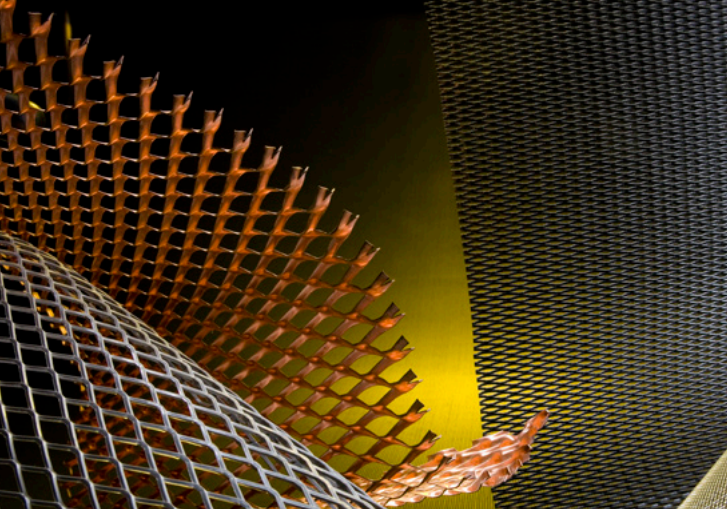

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

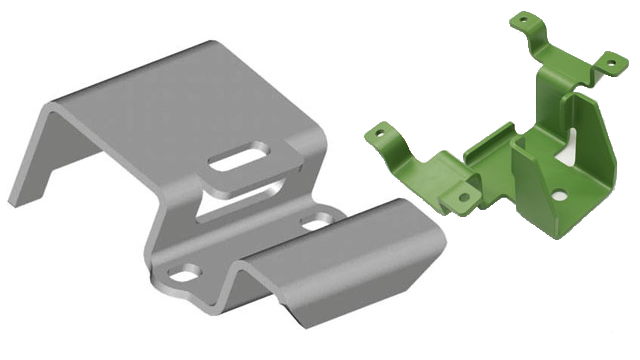

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services